All media displayed are in the public domain, copywrite-free, or permission was given for use

Please contact me for any consulting requests

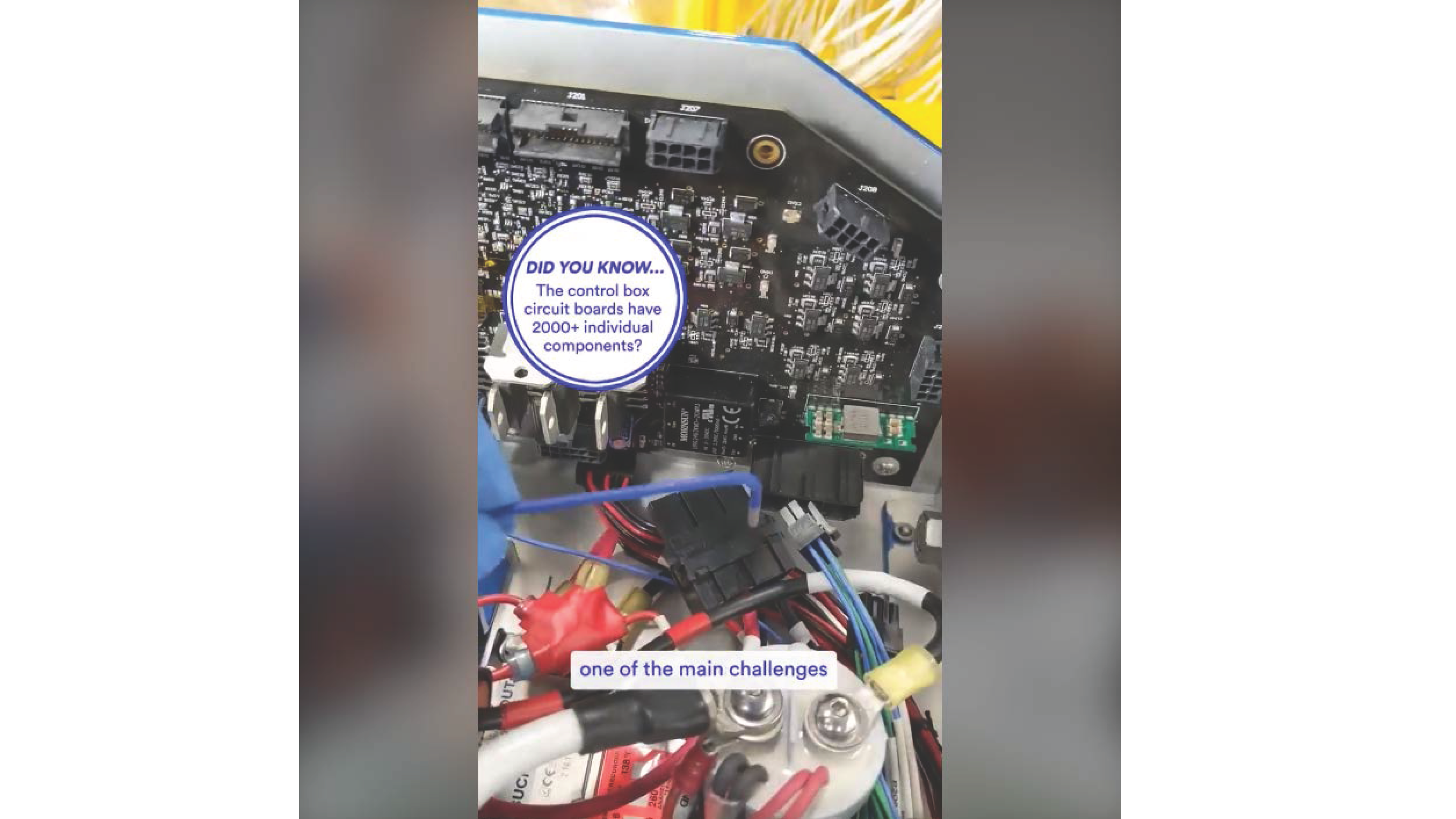

Skyryse aims to make general aviation safer and simpler with an advanced flight control system.

I joined Skyryse as an electrical integration engineer, developing, testing, and integrating

electrical systems for the SkyOS, a universal operating system for any fixed- or rotary-winged aircraft.

As the EE focal point, I am the responsible engineer for troubleshooting any experimental or

for-credit certification aircraft related issue. With a novel triple redundant flight control system with

many bespoke LRUs, I closely work with the flight test, certification, and systems teams to ensure the SkyOS

system has the same level of safety and rigor as part 25 aircraft.

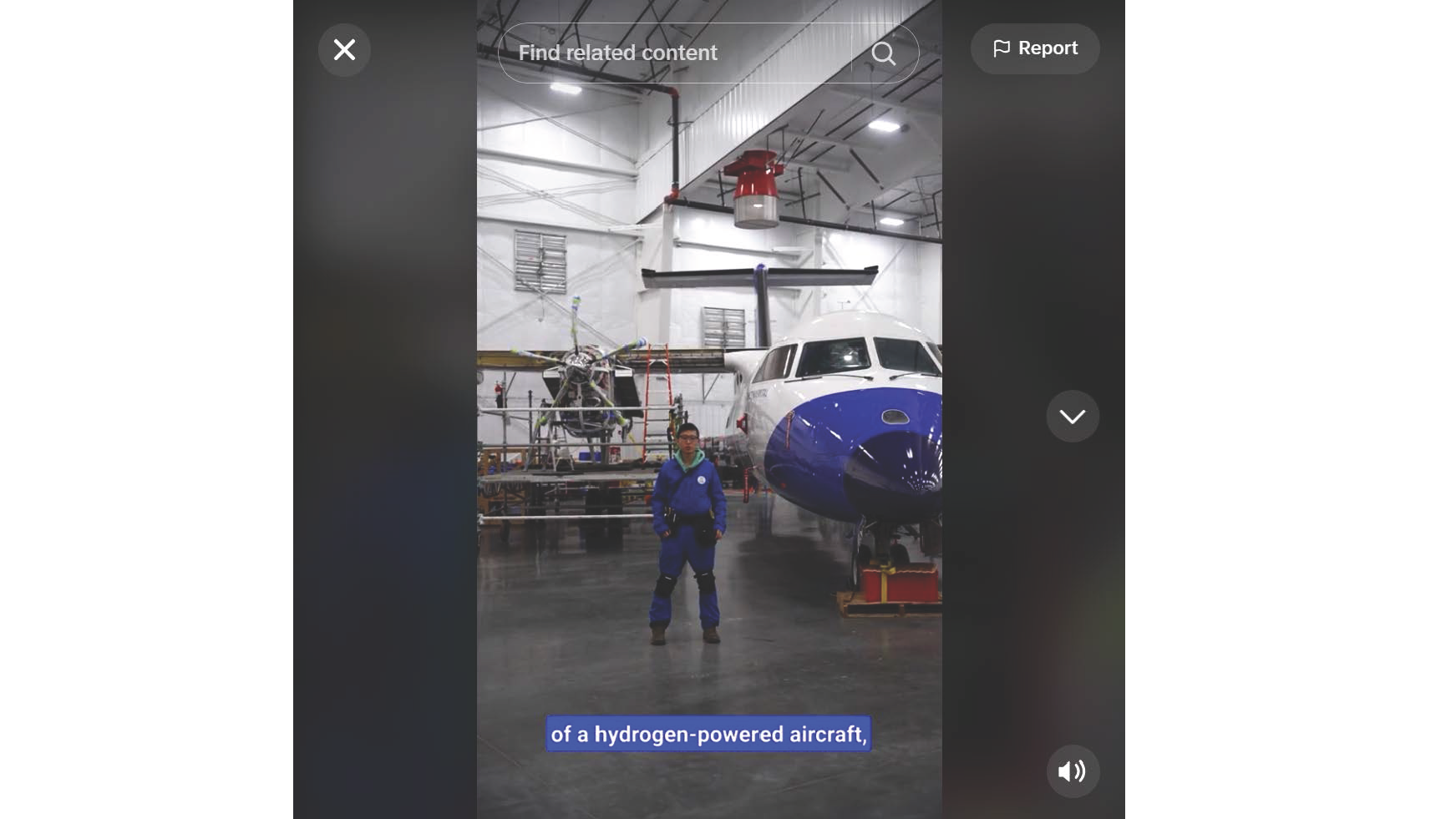

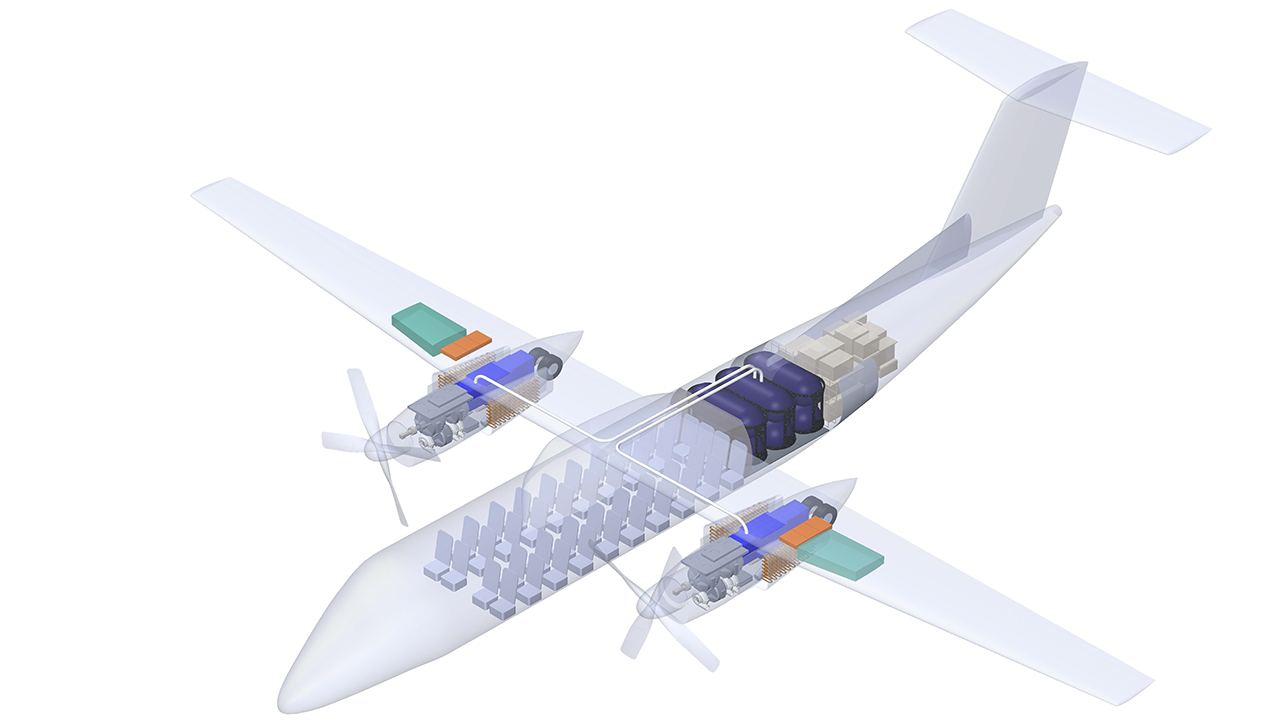

Why hydrogen?

From trade studies to ground testbeds to flight test aircraft, I was deeply involved and intricately familiar

in the development and operation of hydrogen fuel cell and electric powertrains. Combined with working

knowledge of the

value chain, airline operations, supplier relations, investor expectations, and regulatory requirements,

I often share my experiences with investors, partners, media, and other interested parties.

If you have any questions I'm happy to share my thoughts and experiences!

![Bigger Iron Bird with 1 MW of fuel cells and 750 kW electric motor with [half] the powertrain engineering team, completed in 12 months](images/UH2_4.png)

Universal Hydrogen aimed to decarbonize aviation using an end-to-end hydrogen logistics network and a

hydrogen electric aircraft powertrain. With $100 million raised, at one point it had 100 employees in

offices around the world.

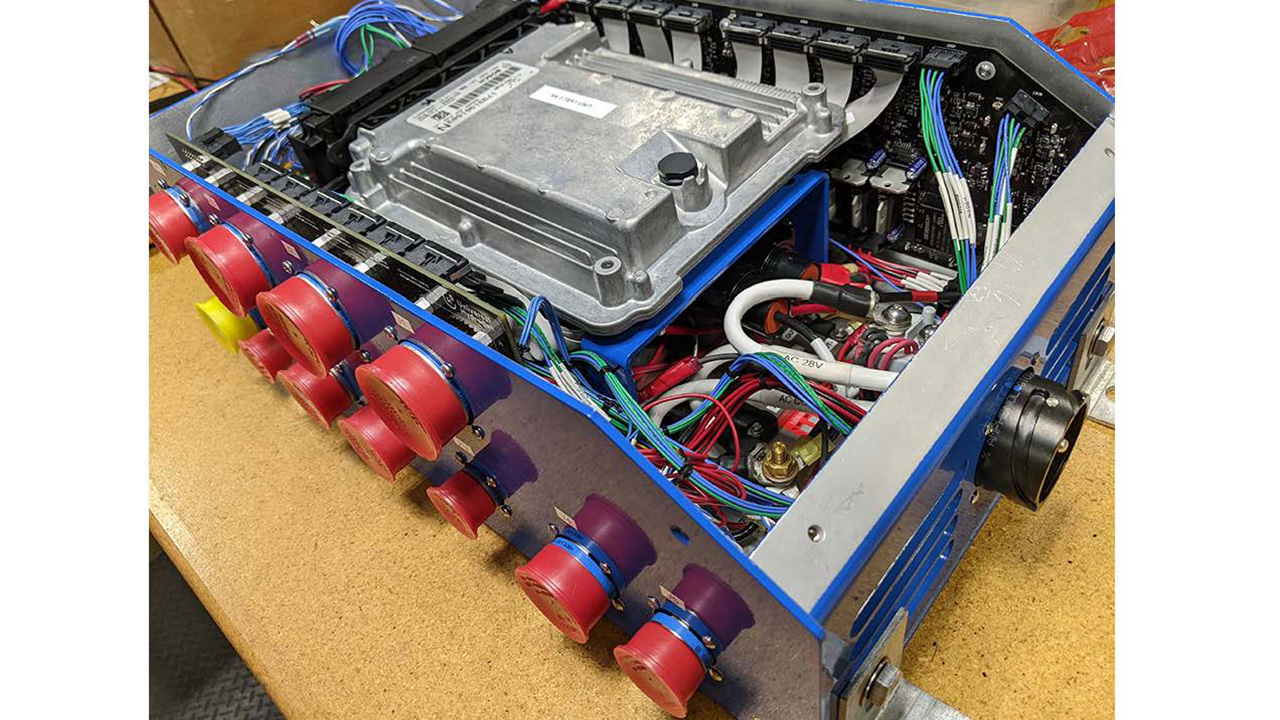

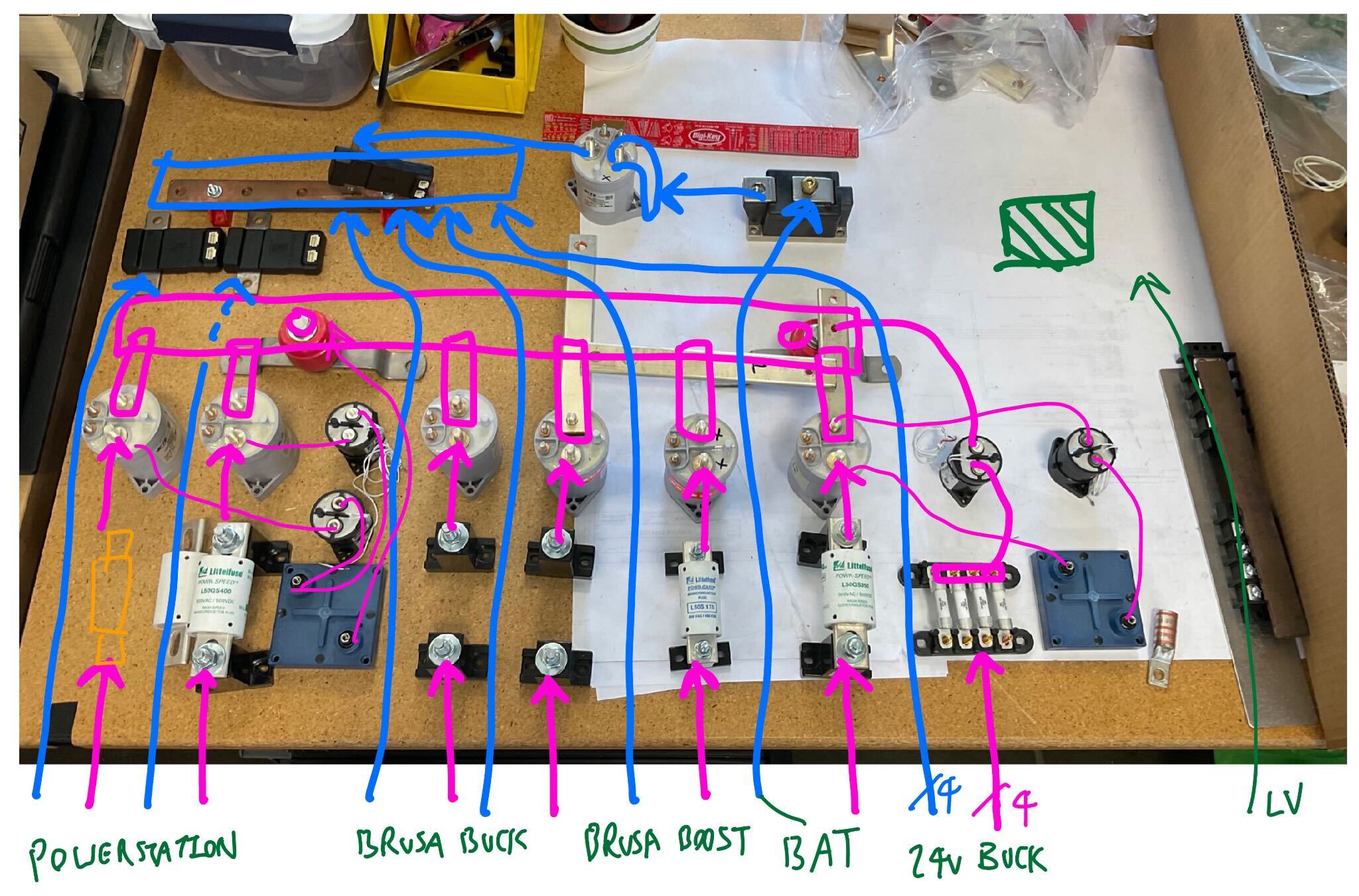

I started my career with UH2 and directly enabled the company to achieve tremendous innovation and

accomplishments in such a short time frame. Working 80 hour weeks on average means that I was able to

compress eight years of experience into the four years that the company existed. Wearing multiple hats,

I had the opportunity to work on everything from first order trade studies to investor pitches to public

outreach. But I ultimately specialized and owned anything to do with electrons, including architecture

design, high voltage power distribution, wire harnesses, PCBs, and instrumentation from ground to flight

testing.

As part of the digital transformation effort at Airbus, I used machine learning and advanced optimization tools in order to create a new method to tune a trajectory controller while meeting various technical requirements.

To improve the performance of the A350 landing gear extension and retraction sequence, I performed data analytics on iterations of T/O simulation data. I also supported verification and validation activities to ensure accurate fatigue limitations for new modifications.

I had the opportunity to work with an advanced wireless/IoT sensing system and complete certification work on the A380 during my time at Airbus. I was also very fortunate to have sat in the cockpit of the first aircraft built (MSN001) to complete my tasks!

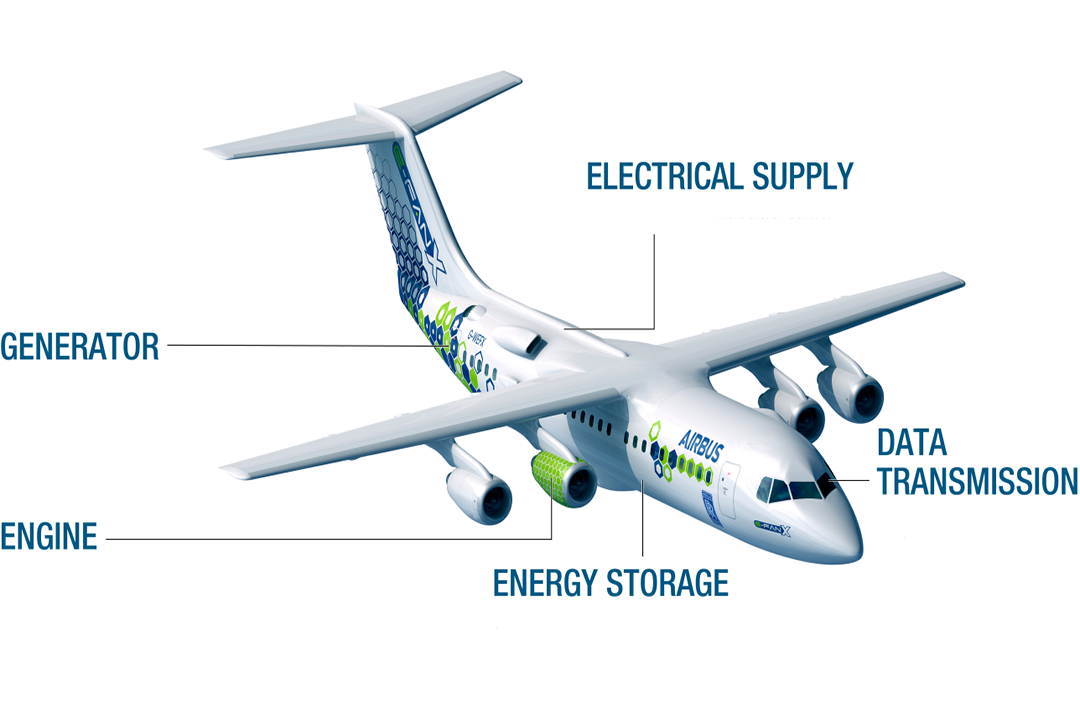

The E-Fan X was a hybrid-electric technology demonstration aircraft

built by Airbus, Siemens, and Rolls-Royce which was

cancelled in April 2020.

I supported efforts to create a static display unit for the

Paris Air Show 2019 by designing a scale model representive of the hybrid electrical power

conversion and distribution system through the use of microcontrollers, multiplexers, LED strips, and DC motors.

To meet a foreign customer request, I designed a proof-of-concept HVAC modification to a Hercules and expand its capabilities in extreme environments, while working at Cascade Aerospace.

As a co-op at Cascade Aerospace, I supported a project to modernize CP140 maritime patrol aircraft in both a project management and technical design capacity.

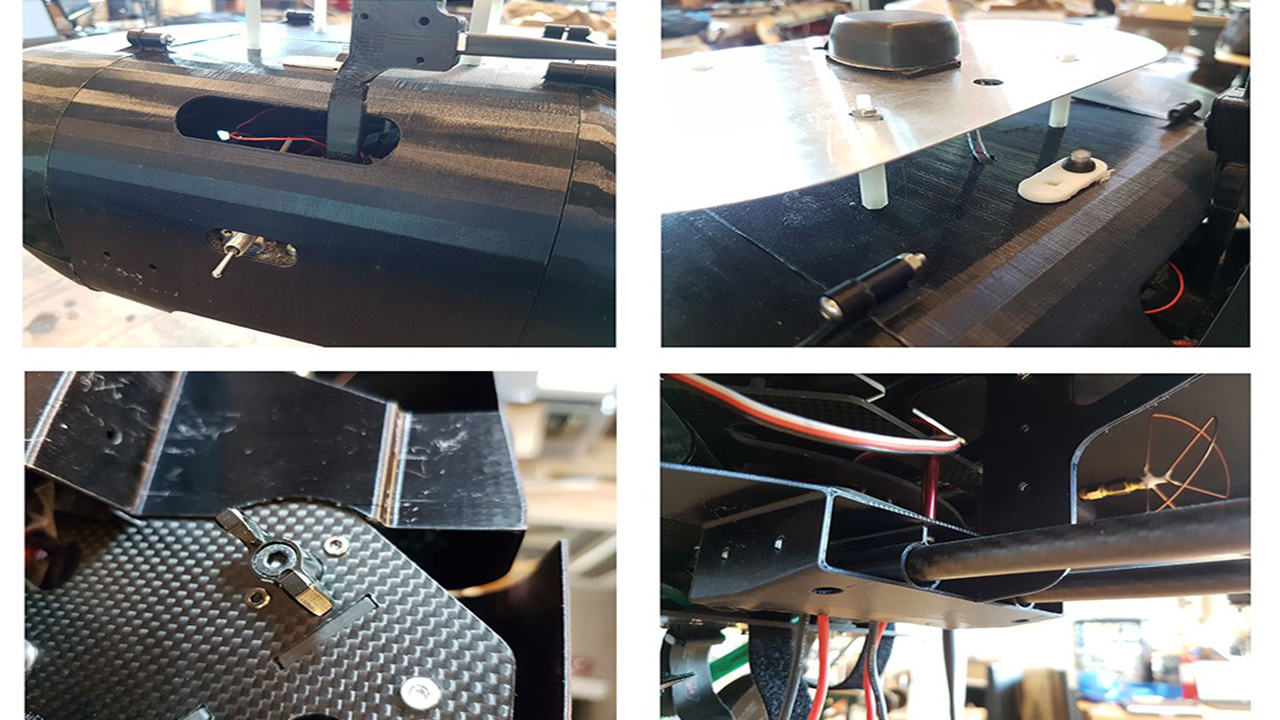

The AlbatrossONE is a subscale research vehicle used as a semi-aeroelastic hinge testbed. Working in the Protospace rapid prototyping environment, I was a key designer of the flight test instrumentation system. I gained invaluable experience while contributing to this innovative project, including RF characterization, PCB design, and scripting custom software tools for both telemetry and machine vision. I was also a ground station operator during flight and ground testing, relaying mission- and flight-critical data, in addition to troubleshooting faults.

The Raven is a large, high-endurance quadcopter with low disk loading with an intended application of

being an aerial relay station for BVLOS drone operations built by the

UBC UAS design team.

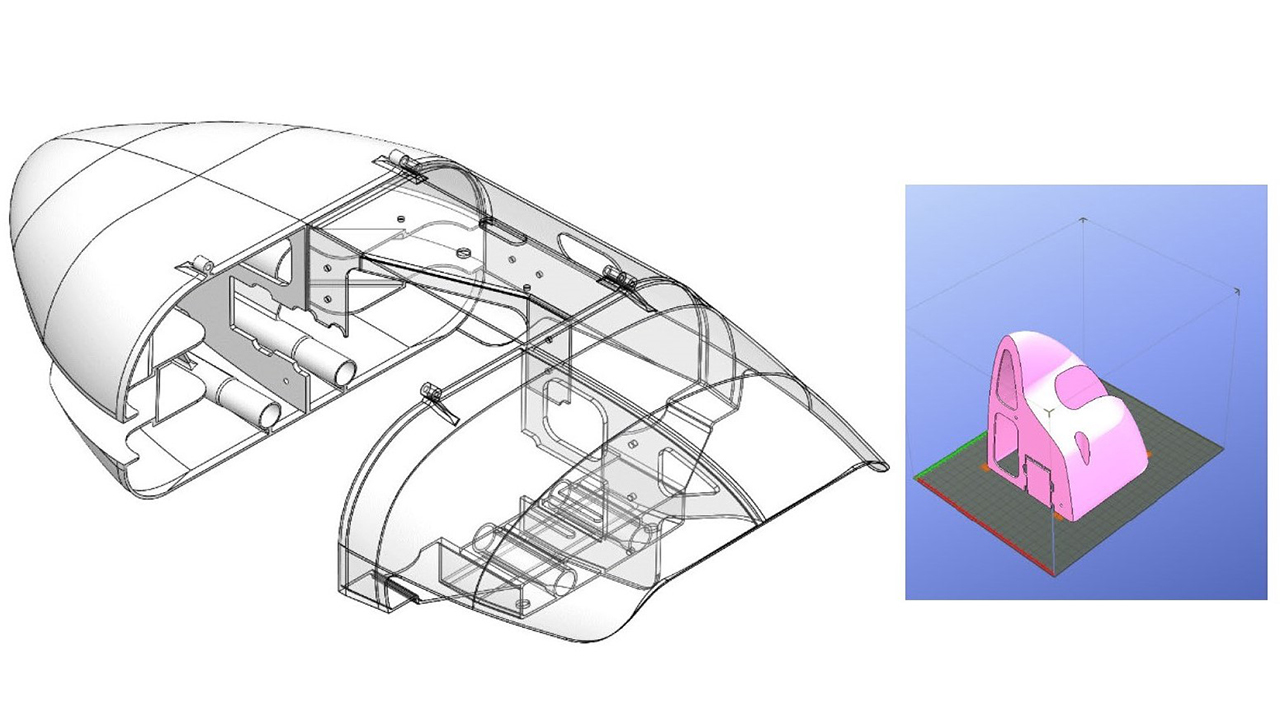

I designed a shell/canopy to be fitted over an existing drone frame to provide ingress protection

in poor weather while maintaining aerodynamics and transportability. It was purposely designed to

accommodate for tolerances and meet clearances, so it had zero interference problems with existing

antennas, transmitters, switches, and the flight controller. The ability to cool the PDB and

collapse the motor booms for transportation was also retained. I successfully 3D printed and

assembled the canopy on the first attempt after many digital mock-ups.

The canopy was praised at the USC 2018 competition

by organizers and law enforcement for aesthetics and the ability to shield internals from the dusty environment.

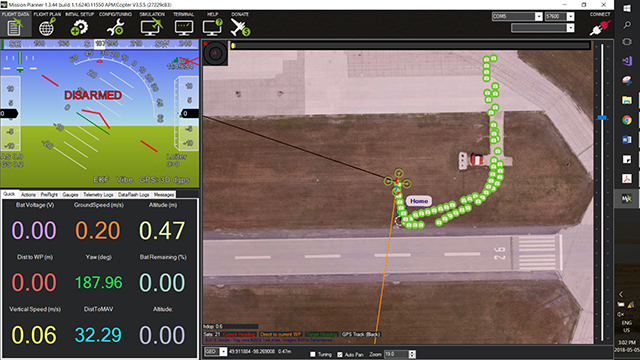

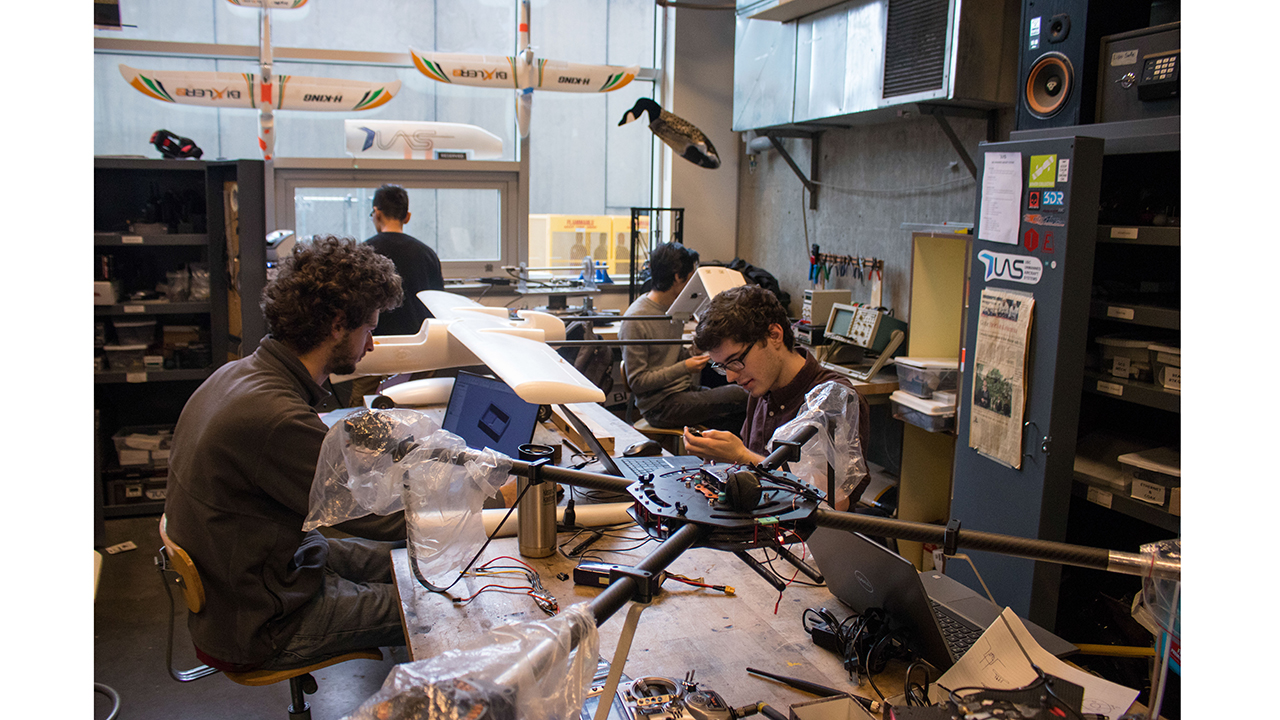

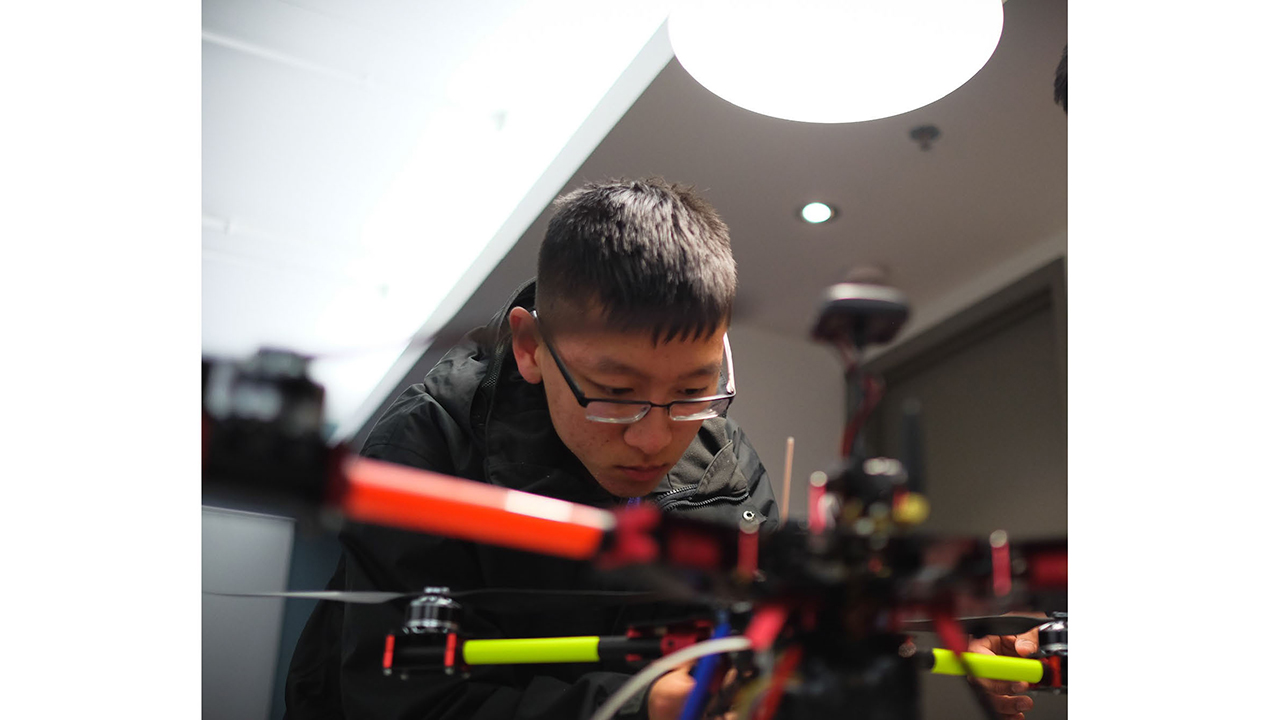

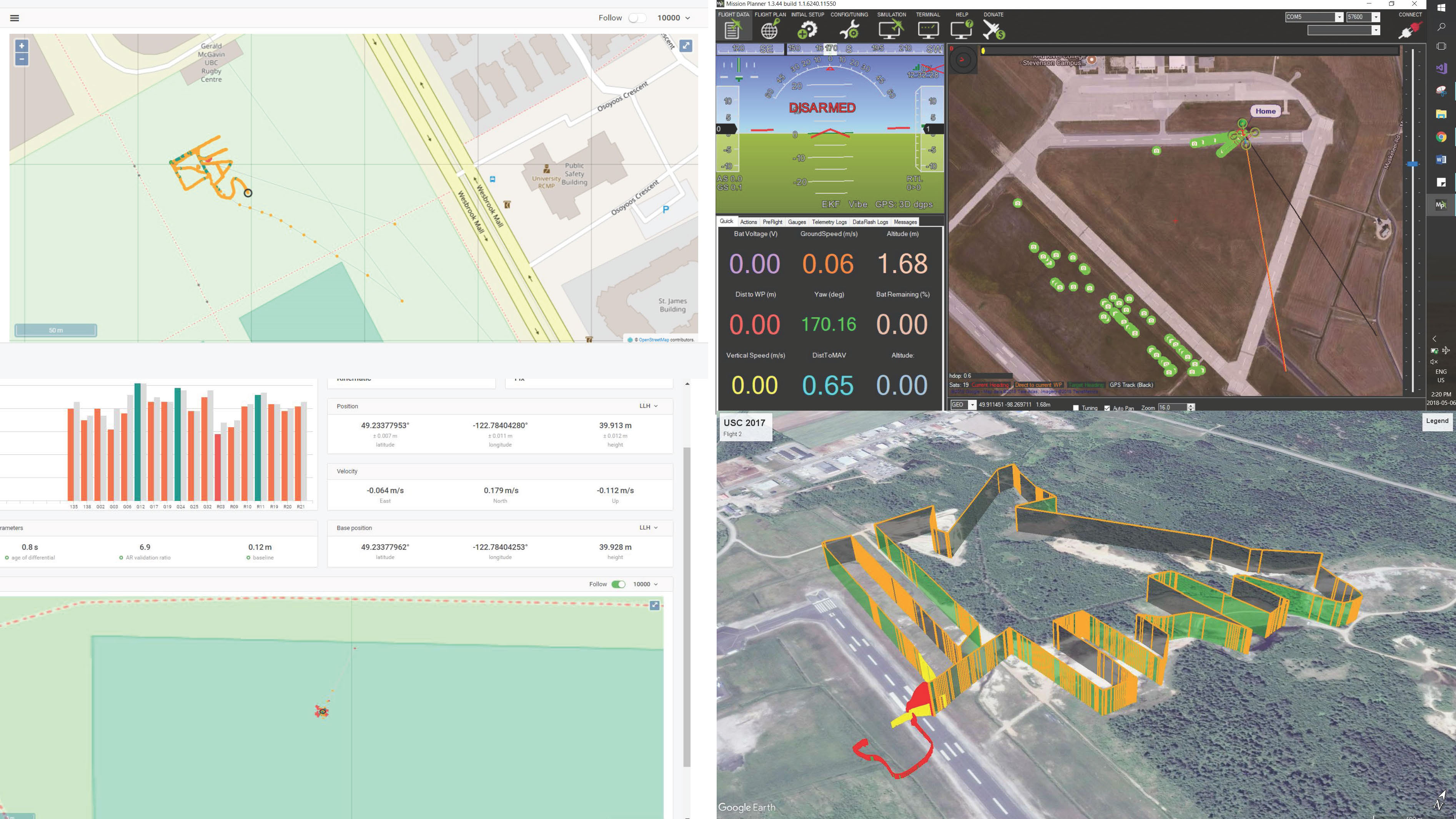

On UBC UAS, I developed innovative unmanned aircraft and their support

systems, such as heavy-lift quadcopters and antenna tracking stations,

while incorporating new technologies like centimeter-accurate RTK GNSS and

augmented reality prototyping tools. My passion for unmanned aviation led me to

become a project manager and then the captain of the entire group of 35

students; I led the team to a podium finish at a national competition for the first

time in the team’s history.

Recognizing the importance of sharing knowledge and experience with the next generation of

engineering students, I'm presently providing technical and projects guidance as an advisor

to enable the current team to reach their goals. I made it a personal goal to mentor a team

of first-year students through the development of an unmanned ground rover.

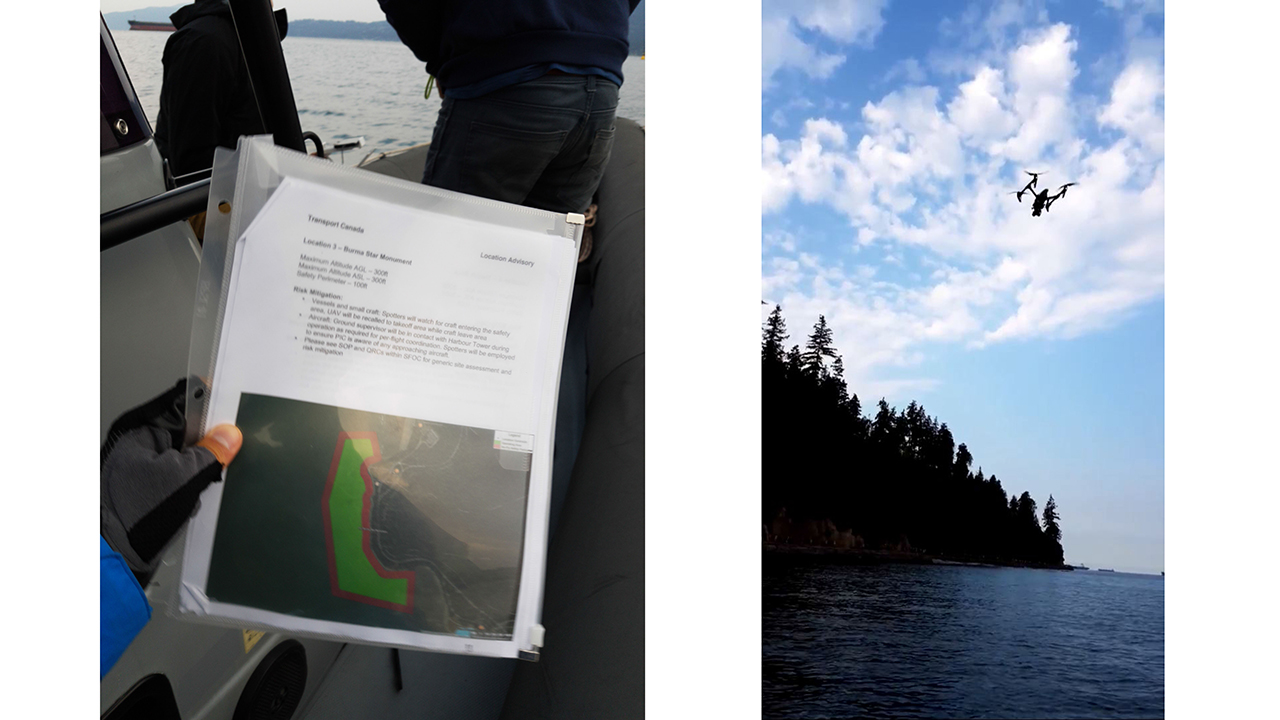

As a UAV operations manager, ground station operator, spotter, or general ground support crew, I've experienced countless flight operations on students teams, through contract work, and in industry. I also held a Transport Canada Special Flight Operations Certificate for several years.

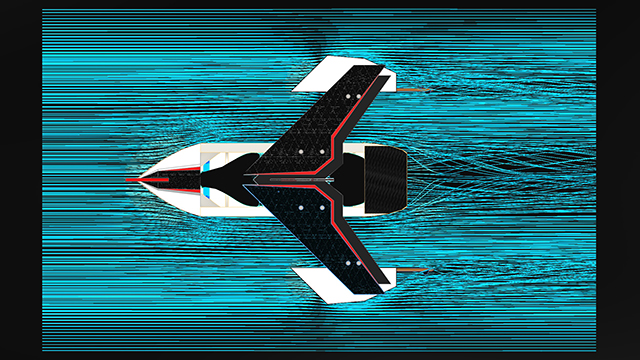

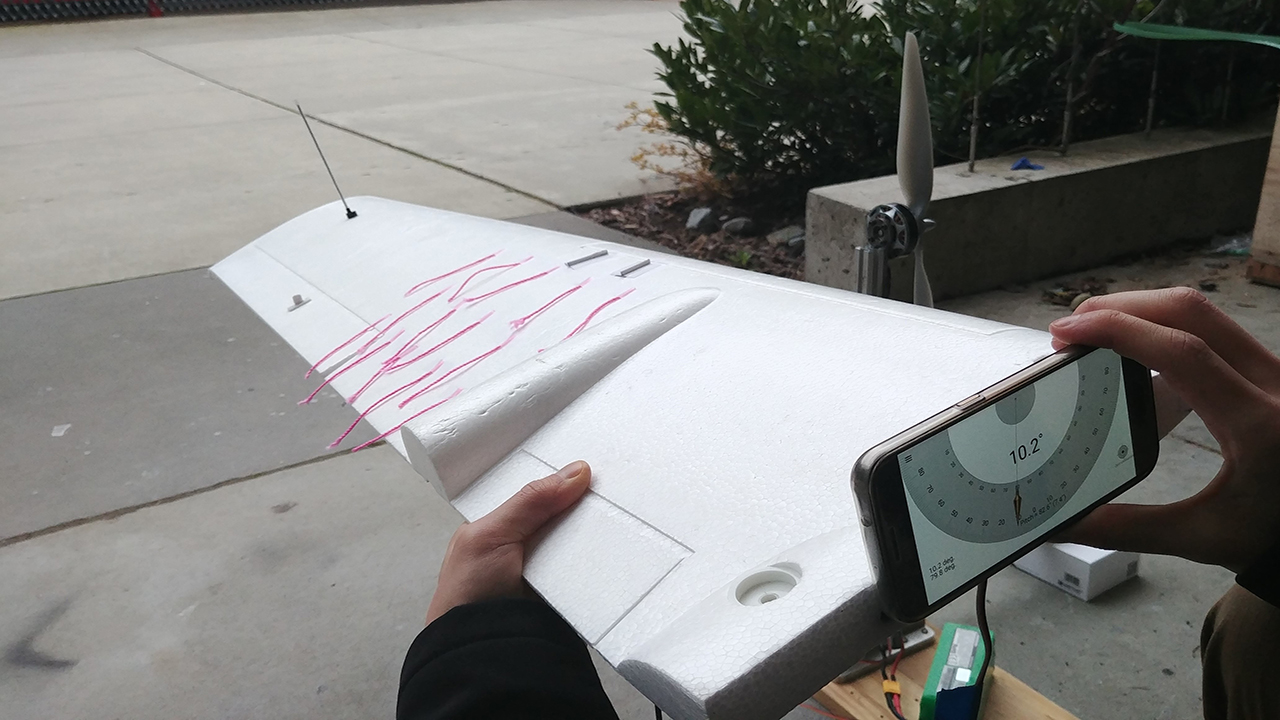

The Dessert Hawk (intentional spelling) is a modified fixed-wing RC aircraft intended to compete at

AUVSI 2018. With competition requirements to perform survey, payload delivery, and overfly sharp waypoints

within the geofence, I led efforts for a VTOL conversion (unfortunately didn't complete due to time

and test constraints).

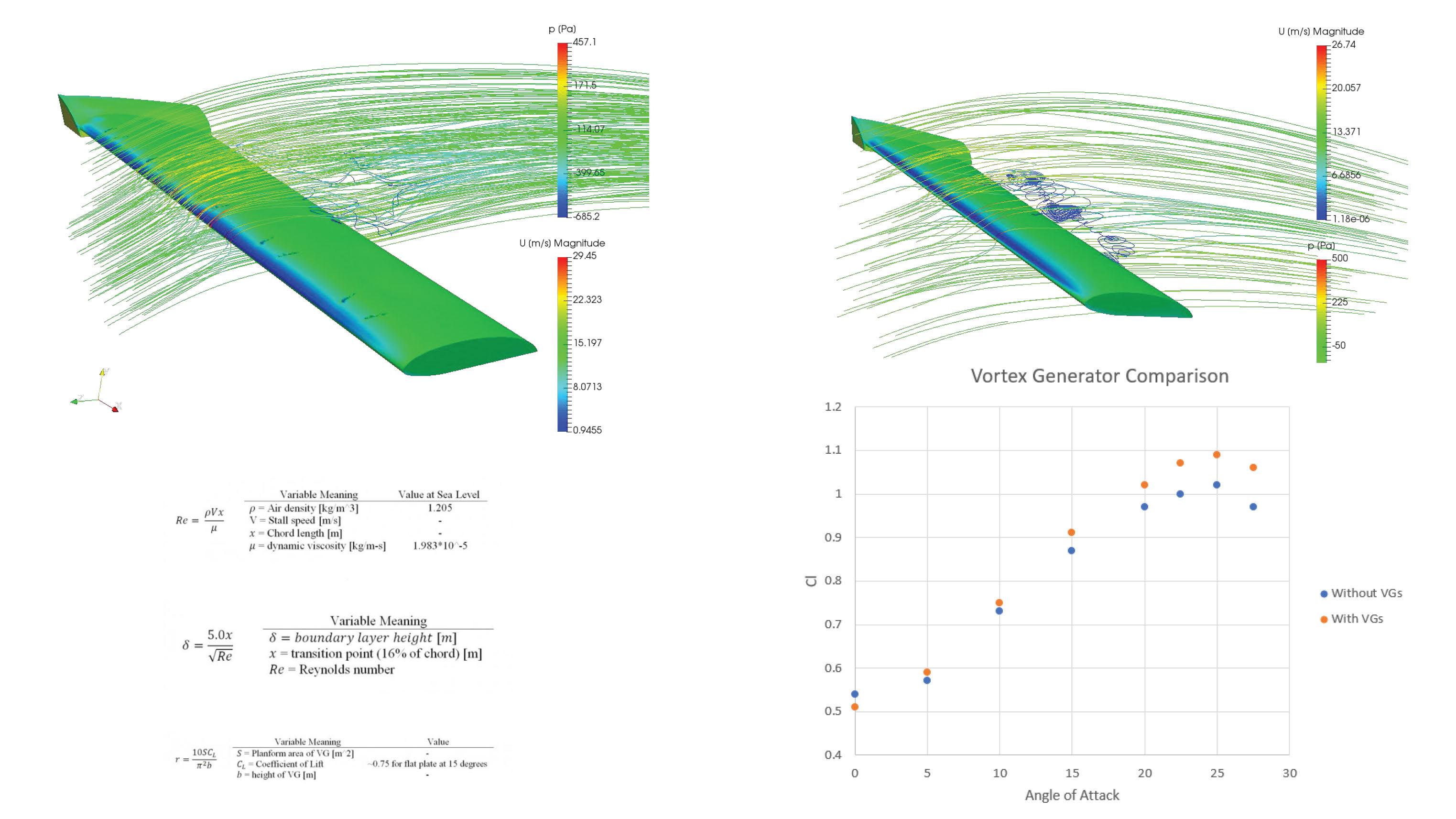

Additionally, I designed vortex generators, which theoretically reduced stall

speed and turn radius by 5% and 8% respectively. Dimensions were calculated as proportions of chord

length, vortex radius, and boundary layer height. CFD simulations were performed using Simscale

(a cloud-based CFD tool), allowing for dozens of simulations to be performed in parallel which

drastically expediting the analysis. After fitting them to the wings, the pilot-in-command

praised the stall recovery performance and increased maneuverability.

Often in the design process of new components, difficulties arise when trying to visualize the scale

of designs or predicting problems without a high-fidelity prototype.

Recognizing this issue and the lack of accessible solutions, I developed an interactive AR program with

the aim of reducing iterations and refining workflow. I developed it with Unity (and Vuforia SDK for target image or surface recognition)

by following online tutorials and documentation. Additional algorithms were coded for the user to

reposition the model, scale objects, and reset the program.

I think that a future upgrade would be to change the SDK to Google’s ARCore and allow the user to change

the CAD file; let me know if you want the APK!

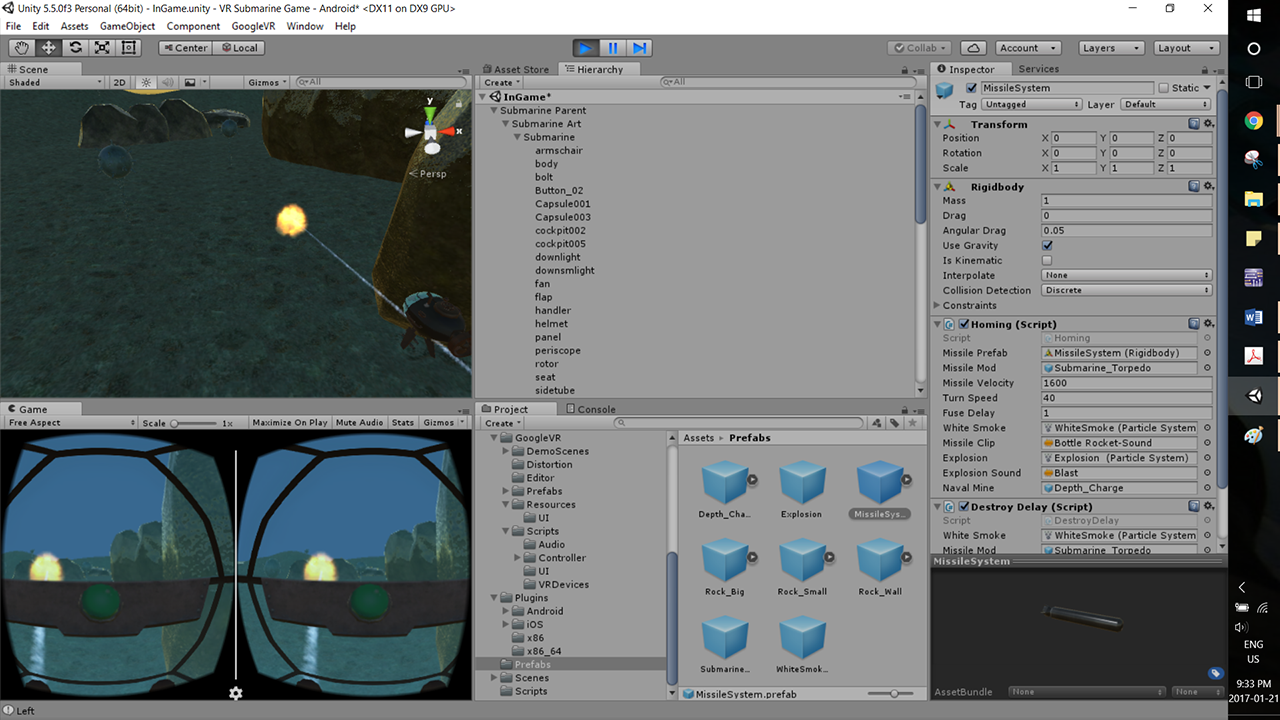

An interest for new technologies led to me attending a workshop on VR applications one summer,

which brought experience using the Unity game engine and VR development. The game is designed for

Google Cardboard with Android Studio. I applied vector math operations for displacement and modified

gameplay by scripting in C# and JS, following tutorials and documentation.

Gameplay includes variable user-following movement, guided torpedoes, and explosion effects.

Sample code can be viewed at github.com/raymondhcyu

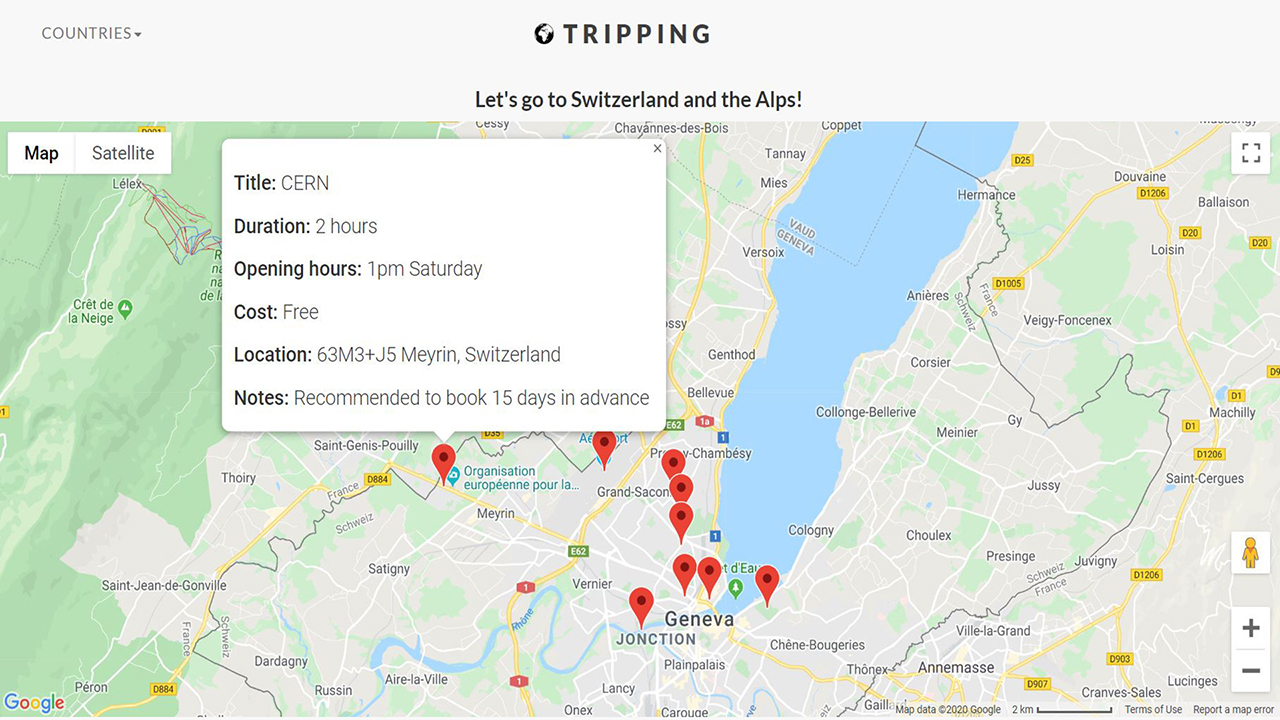

To help plan and coordinate my travels in Europe with friends, I developed an interactive

web-based map utility with Google Maps API, Google Scripts, JavaScript, CSS, and HTML.

Travel information like opening hours, cost, and facts are all updated live from Sheets

(which I use to organize my trip beforehand anyways).

Scripts automatically search for the street address and latitude/longitude coordinates to

reduce manual input, and display the live user location.

While I only realized that a customizable map was already released by Google after this was

created, this project was nonetheless an engaging experience. To increase practicality,

new features such as showing the user’s device orientation and calculating navigation directions

with Directions API can be added. The webapp can previosly be viewed at: quaternion.me/pages.

Update as of 2025: APIs deleted.

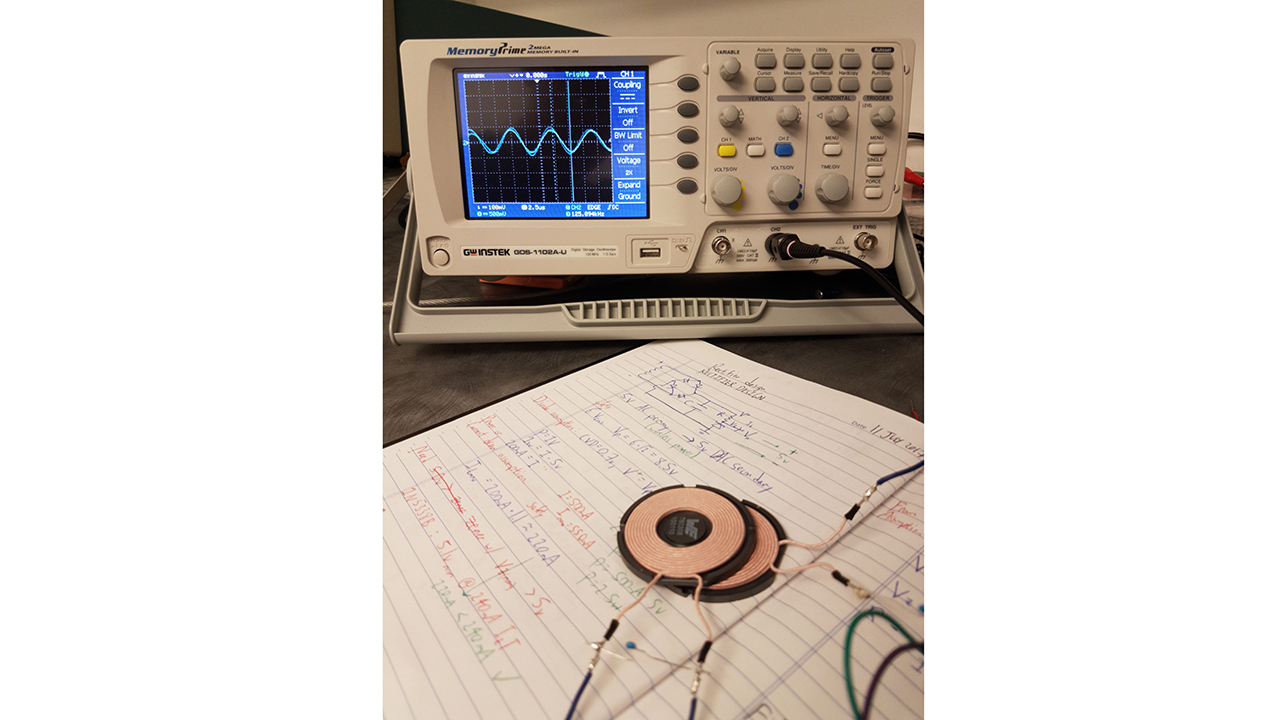

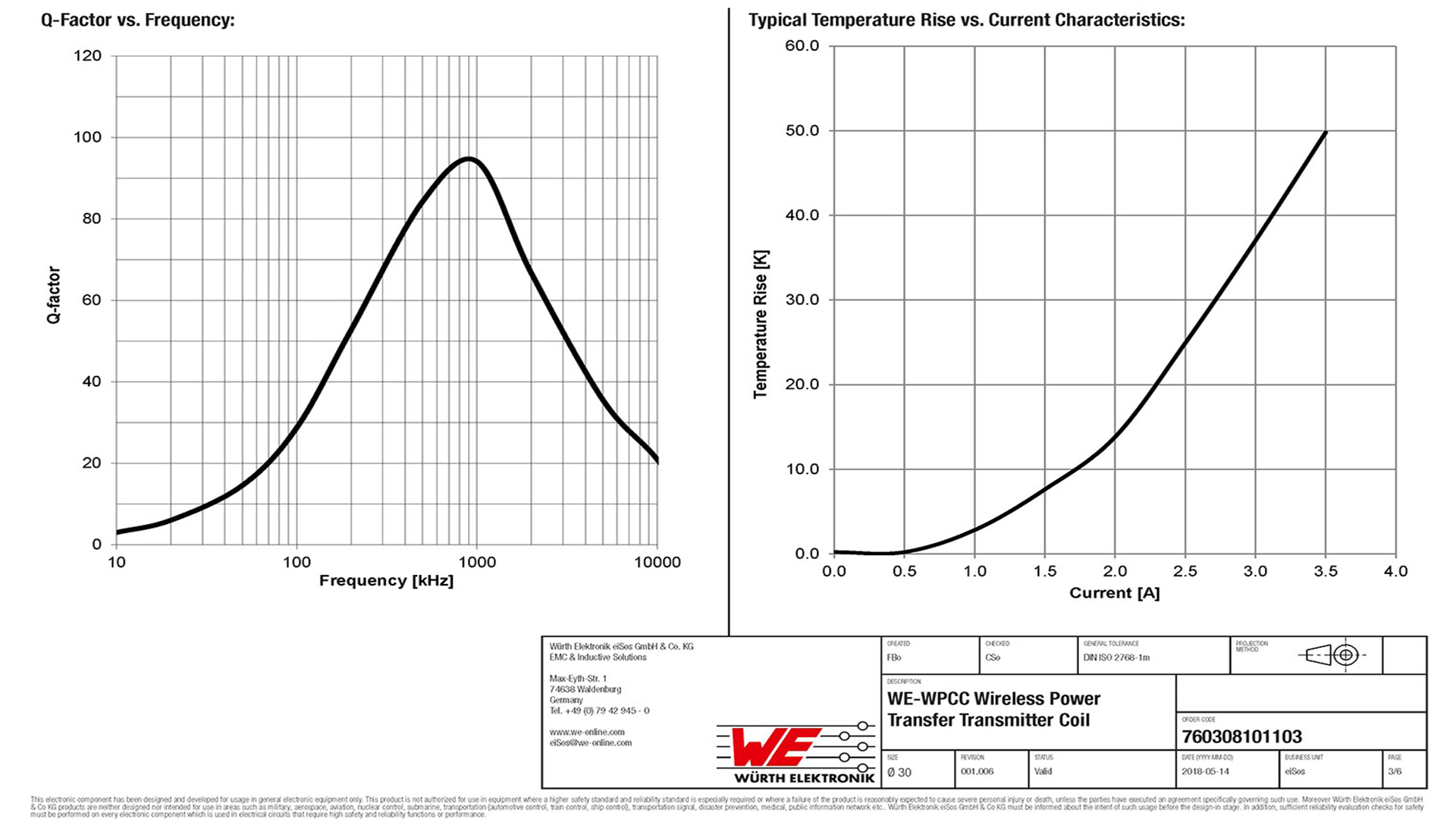

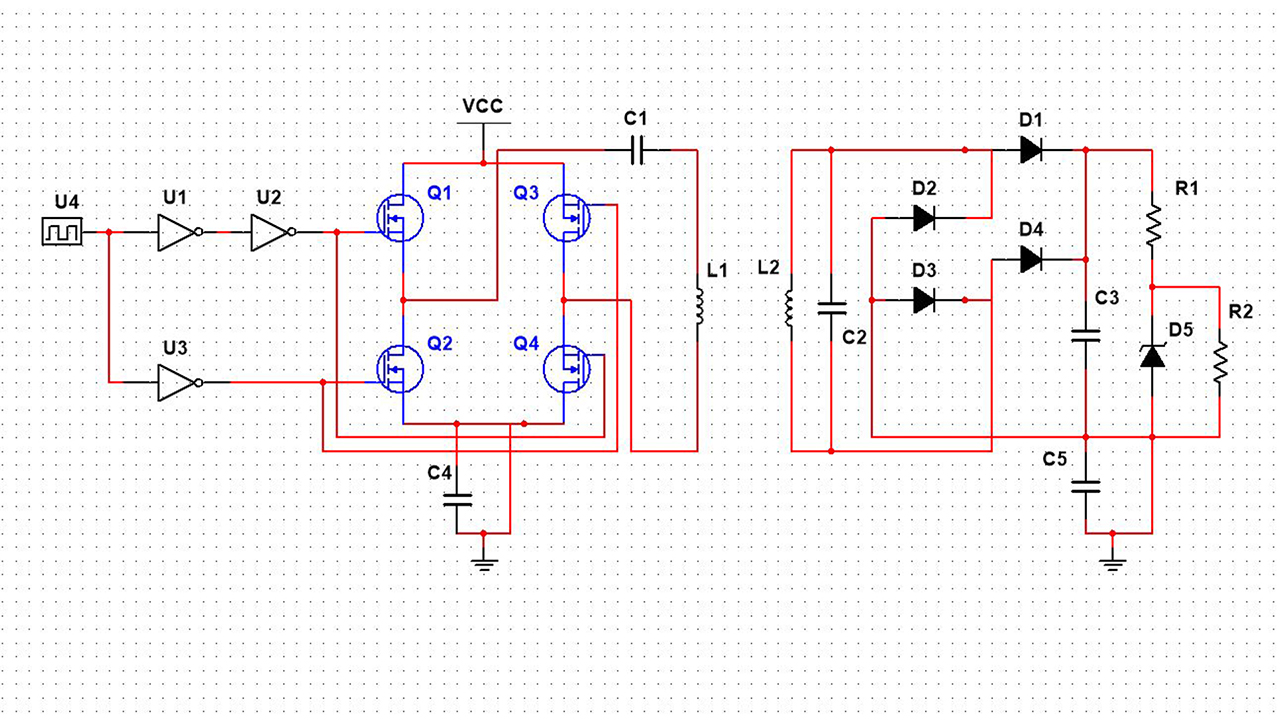

Wanting to avoid the nuisance of tangled wires when charging my phone, I attempted to make a wireless

induction charging station. I designed the circuit using online tutorials, forums, and class notes,

with components sourced from DigiKey. Raspberry Pi and logic gates used to provide PWM to H-bridge

and to regulate voltage. Induction was optimized by maximizing the Q factor at ~150kHz according to

the coil datasheet, and I calculated the capacitance required for magnetic resonance.

Although an improvement would be to move the circuit onto PCB (probably going to be clunky)

and actually charge my phone, I think that it'd be neat if I can study and transfer energy via Qi standards.

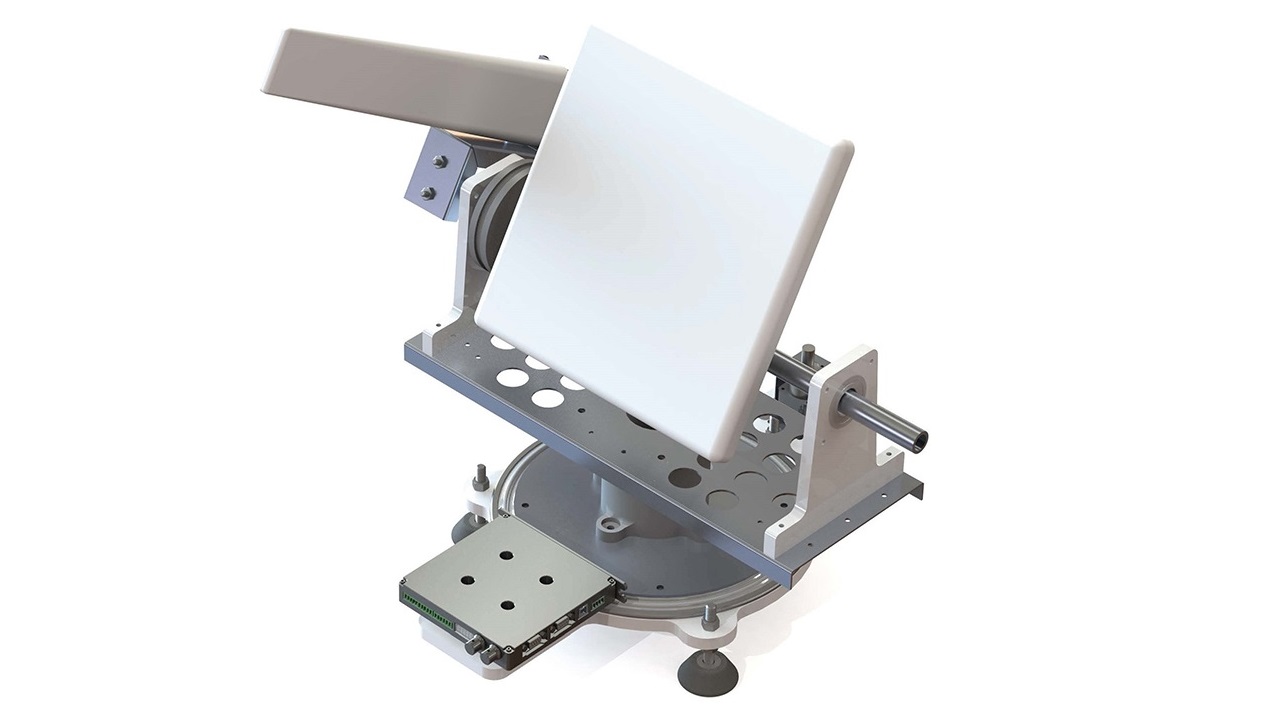

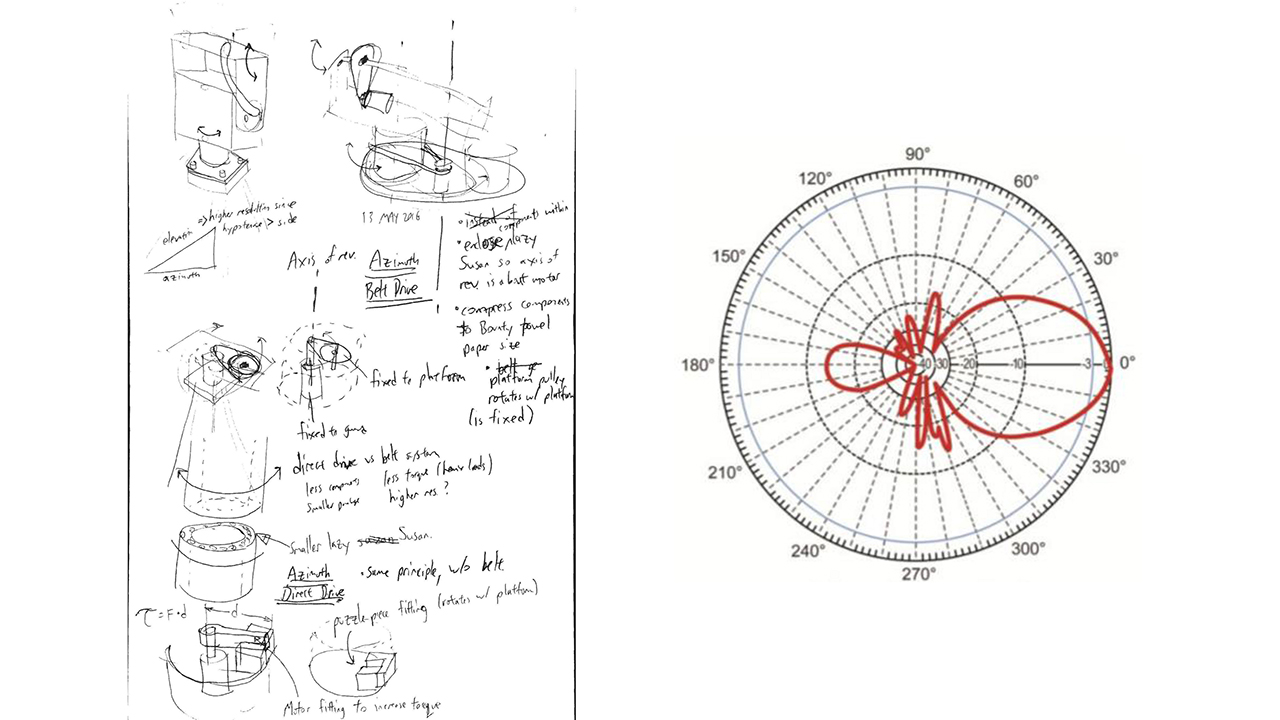

To enable a reliable datalink between ground control and UBC UAS drones, a directional antenna

needs to be pointed at them. The Ground Control Antenna Tracking Station (GCATS) can support a

high-throughput datalink so images and videos can be sent live to the ground for processing,

instead of waiting for the drone to land and remove the SD card for post-processing. Multiple

evolutions of the GCATS was deployed at UAV competitions, tracking drones and relaying mission data.

I designed, tested, and manufactured the Mk1 and Mk2 models, and calculated operating parameters

dependent on drone and RF performance. I also developed a feedback loop with an IMU and performed experiments

to test the motor torque, GPS and IMU accuracy, and signal attenuation. High-resolution rotation

in yaw and pitch was achieved using stepper motors and timing belts. A software program developed

by the UAS software team parsed GPS coordinates from MAVLink and commanded the station

to rotate and minimize the vector difference between the drone and the ground.

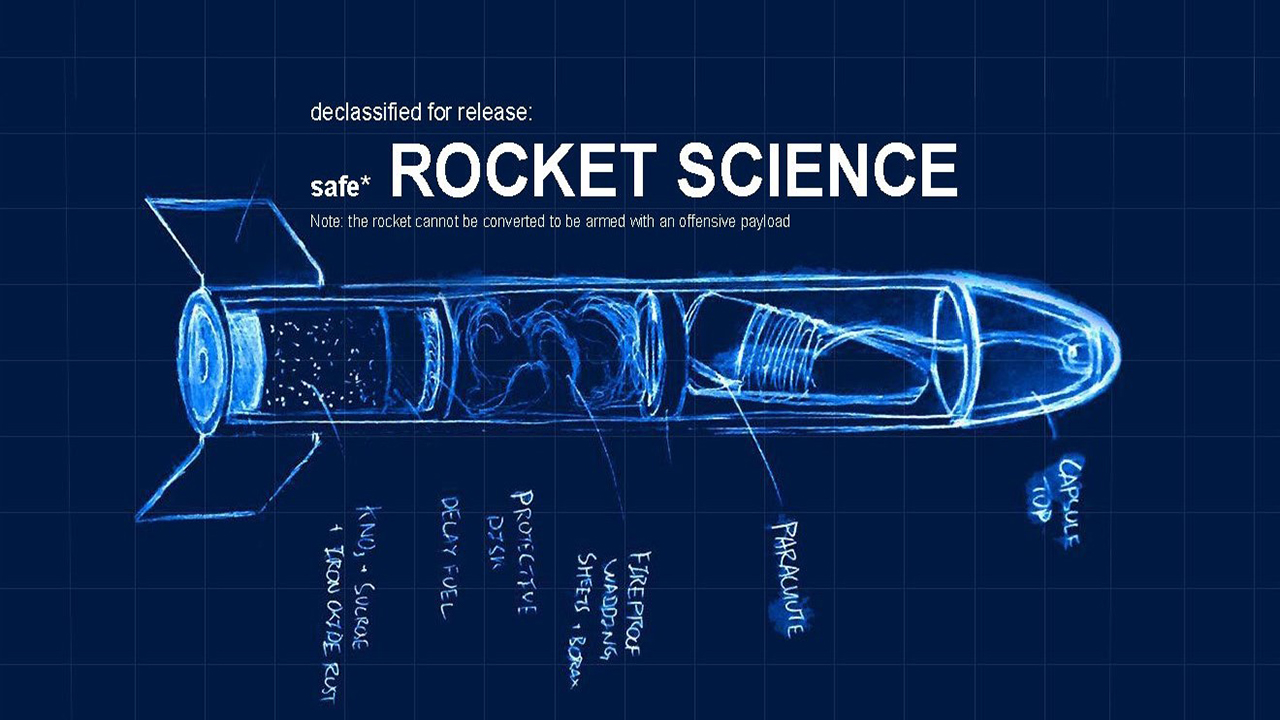

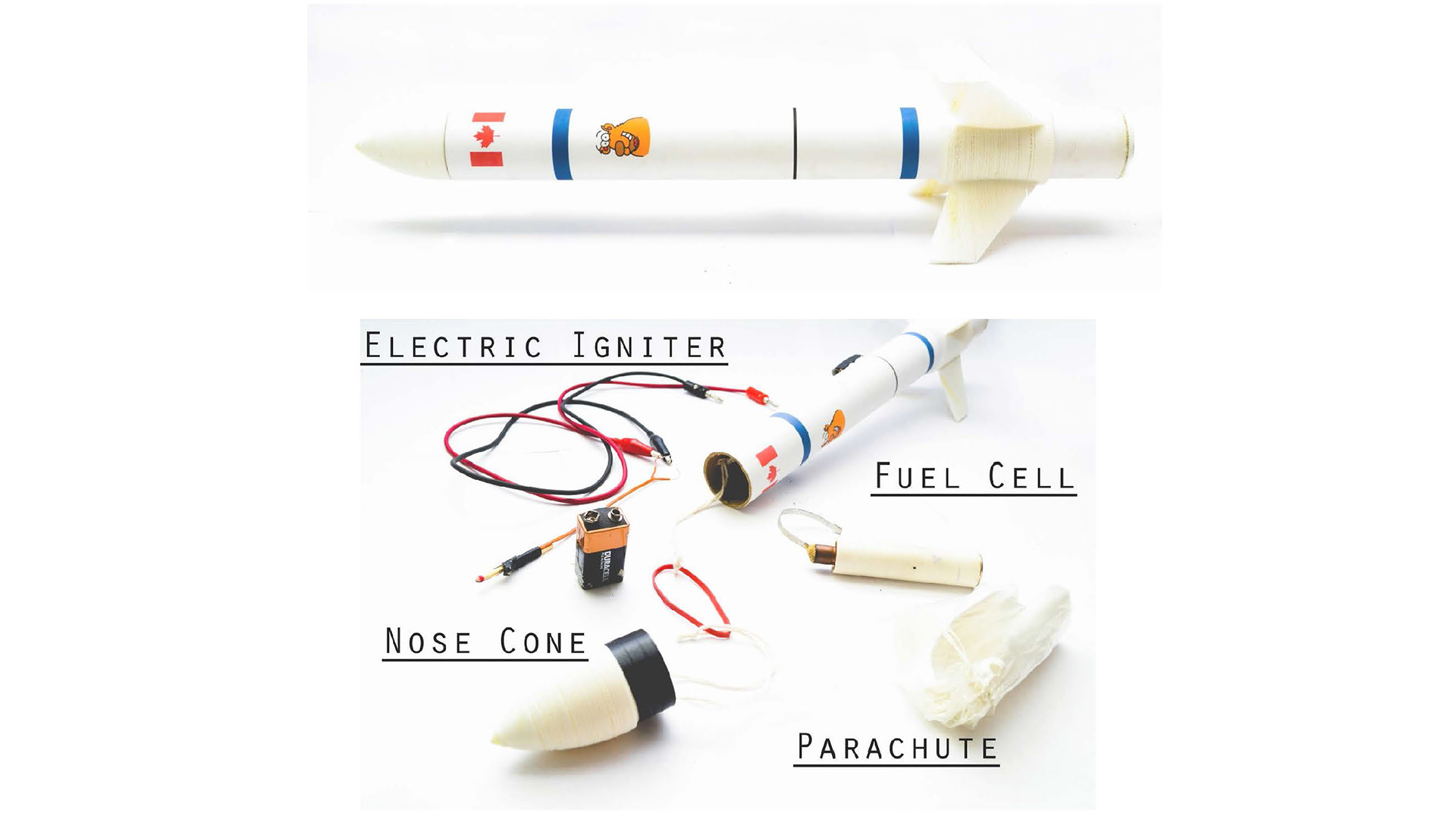

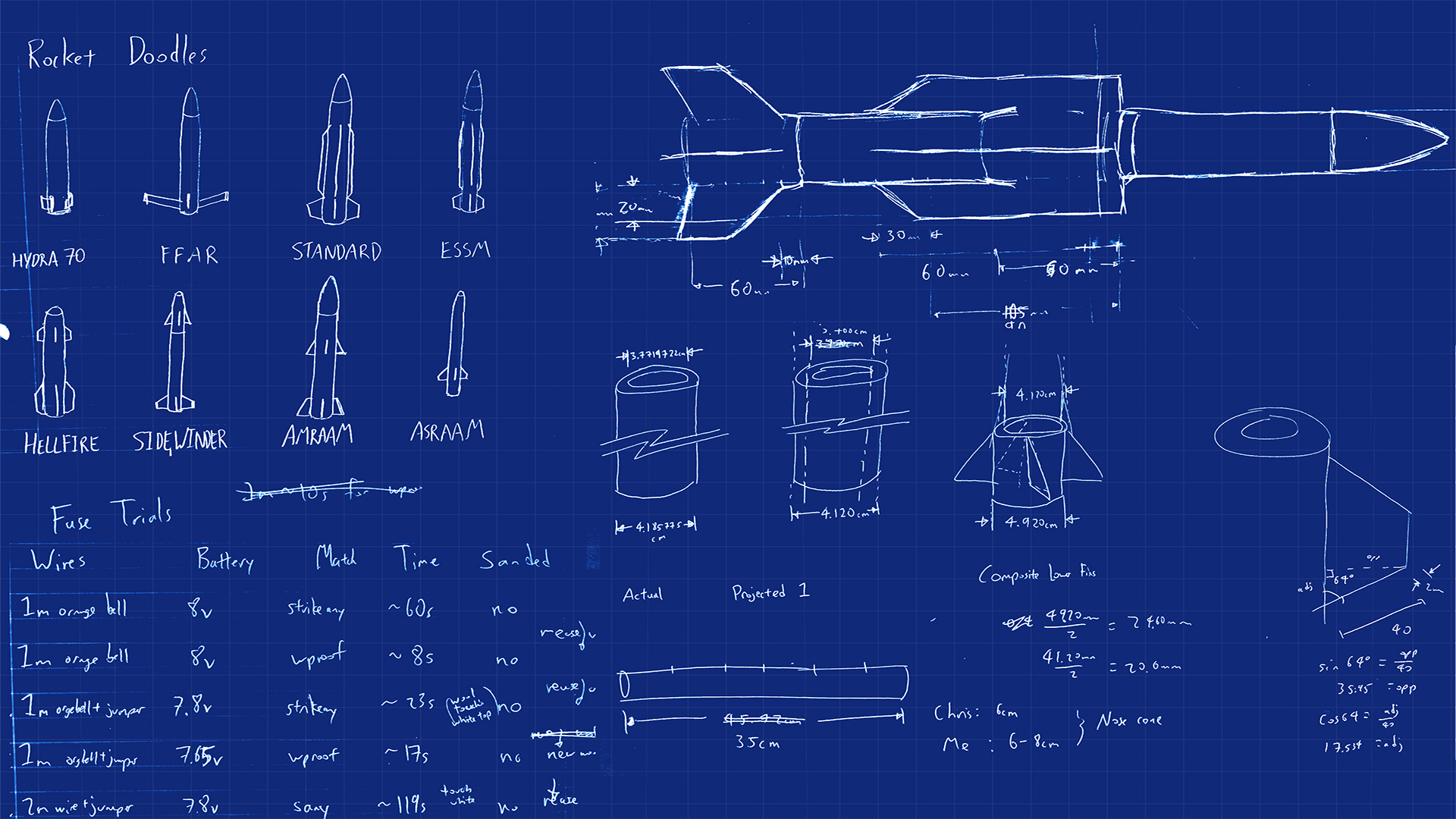

As a final project for a highschool AP chemistry project, I created a solid fuel hobby rocket The fuel cell comprised of potassium nitrate, sugar, and sulphur, while aerodynamic surfaces were 3-D printed. Flame-retardant paper lined the interior to protect the fuselage against the delayed parachute charge. I tested individual subsystems like the parachute and motor using estimated flight parameters.

You're on it now!

As I always wondered how websites are made, I decided to create my own website

instead of using a template. I used HTML, CSS, JS, Bootstrap, and enabled Google Analytics.

(Using NameCheap, CloudFlare, and GitHub for the domain, security, and hosting.)

Comments or suggestions? Let me know!

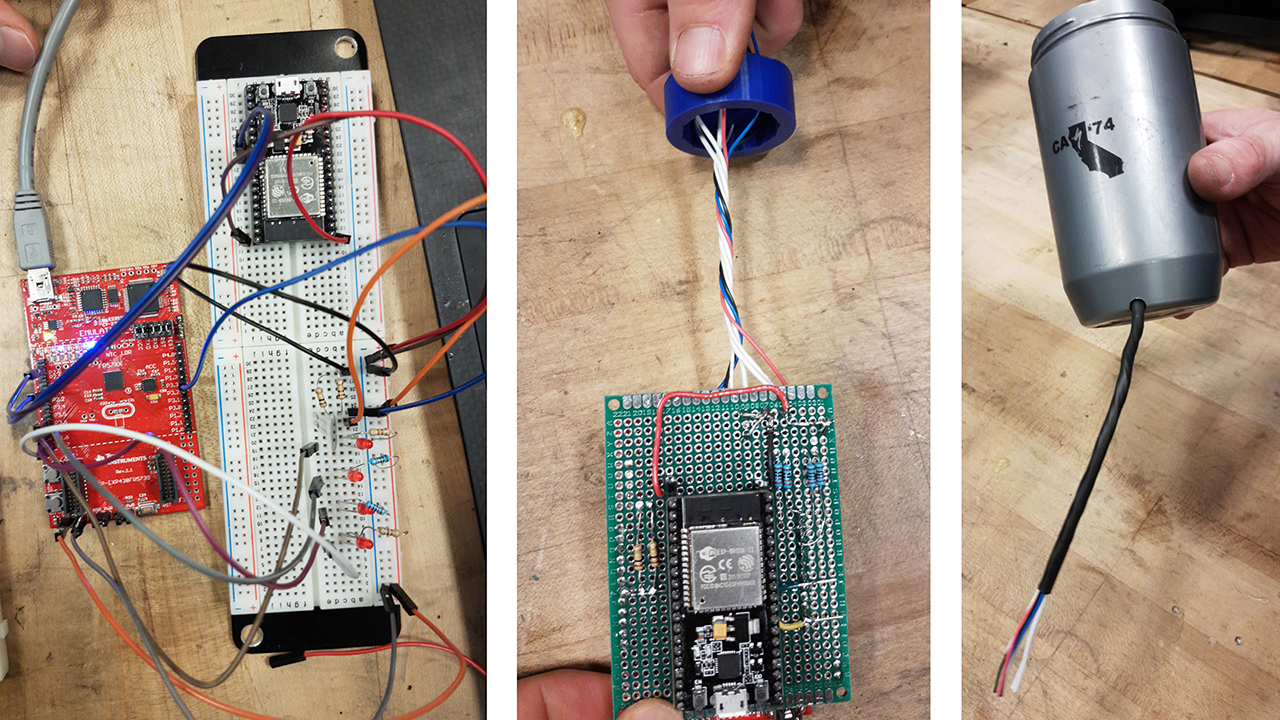

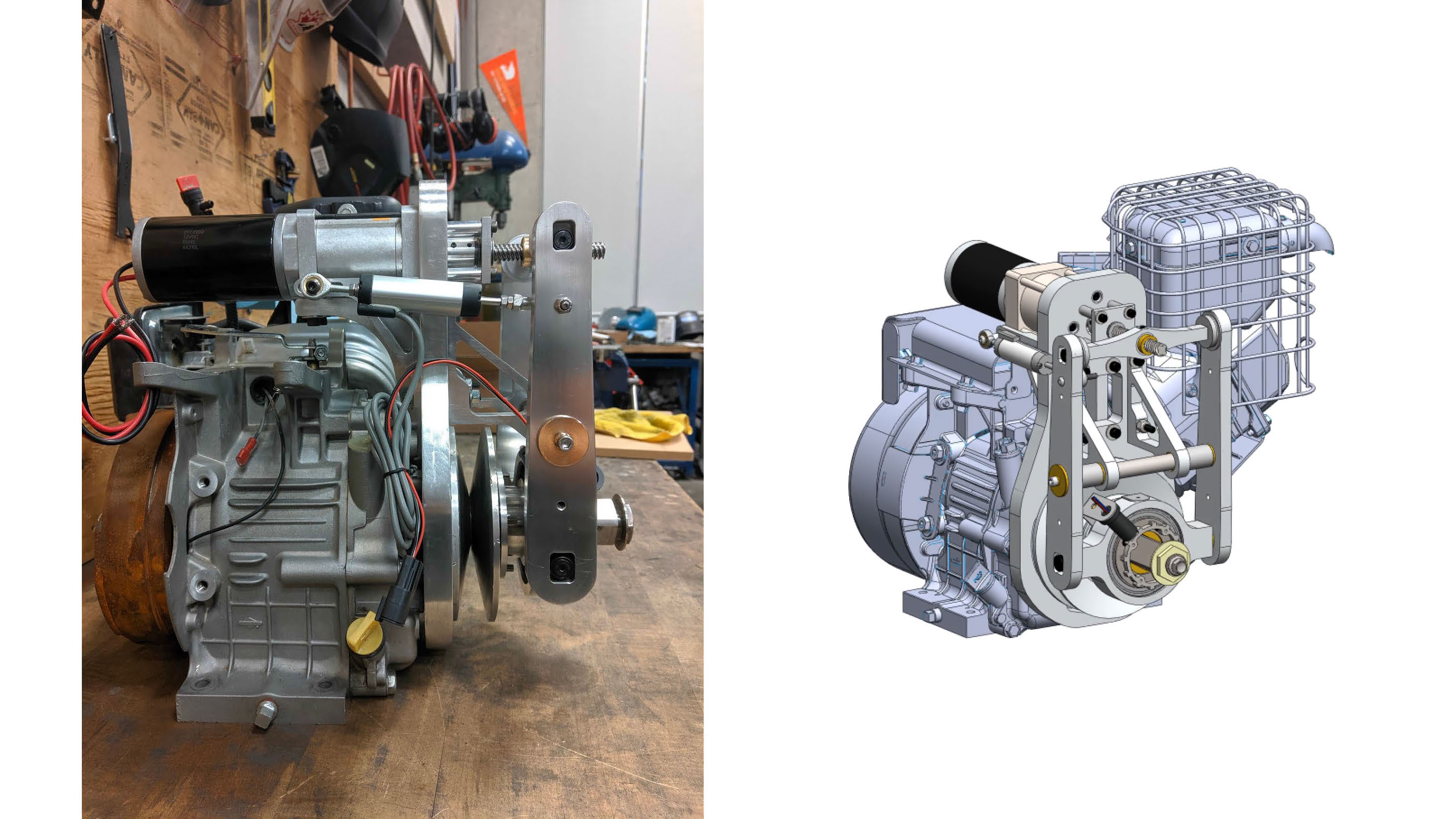

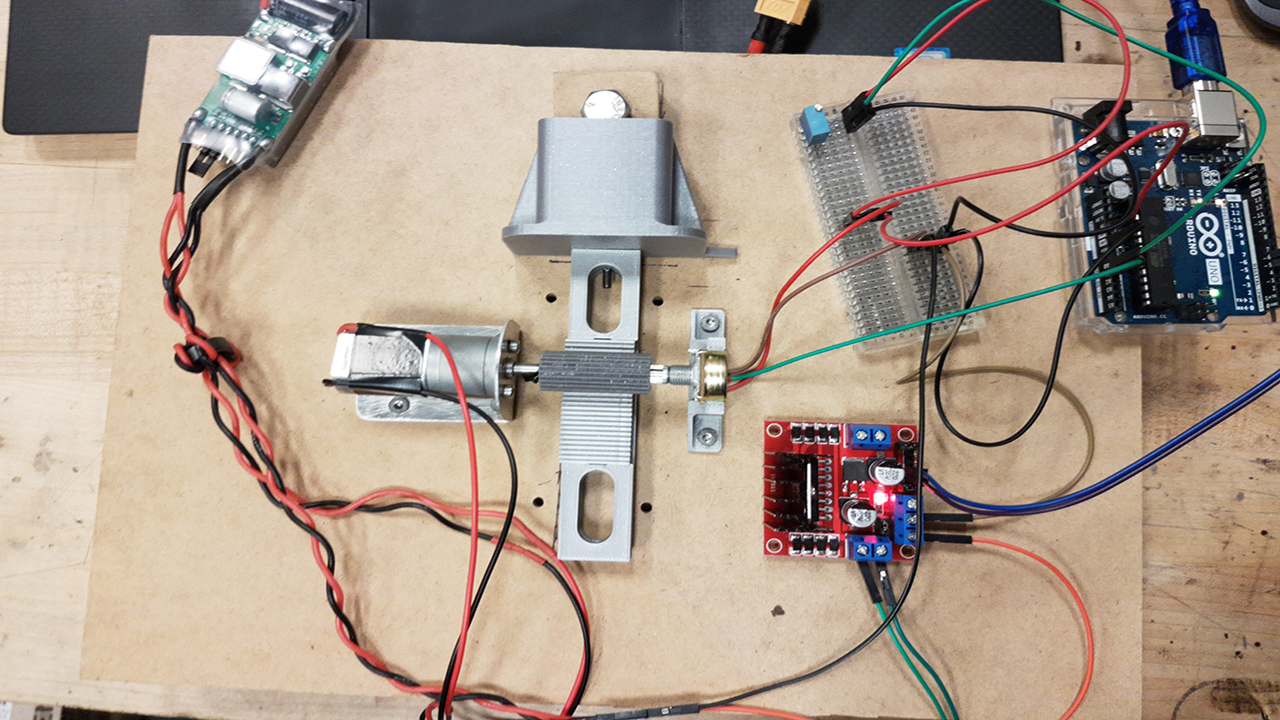

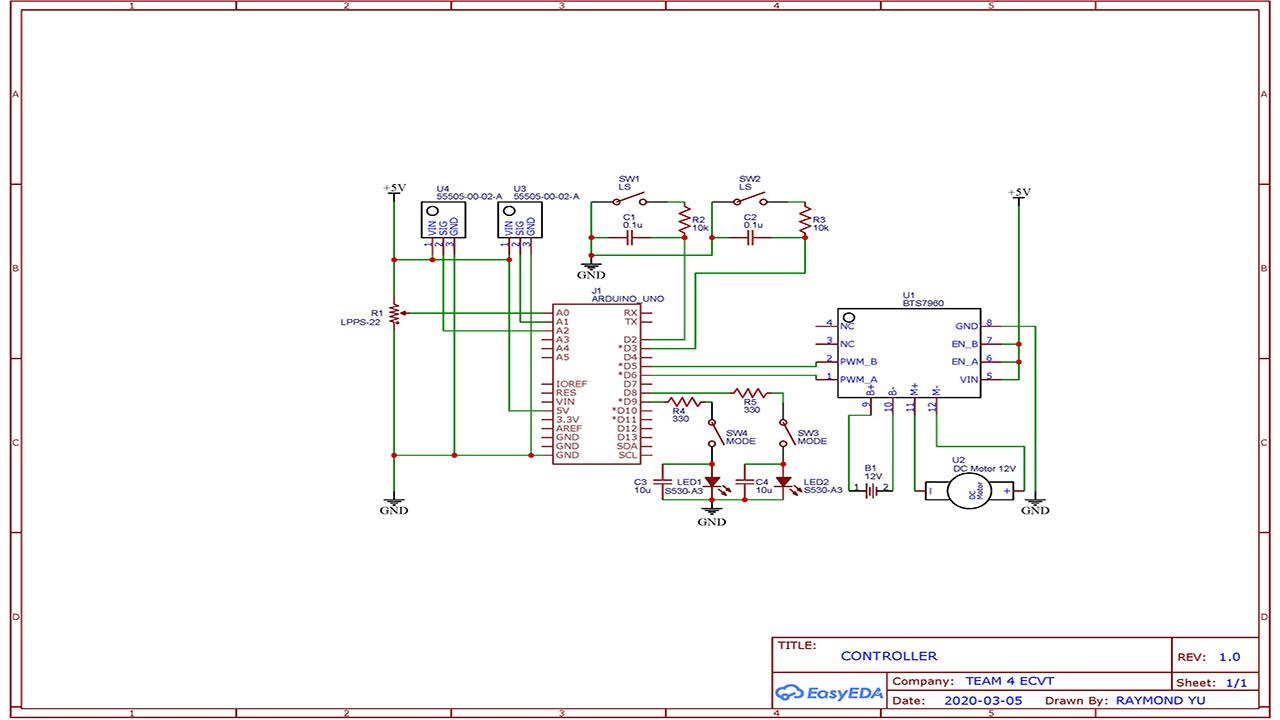

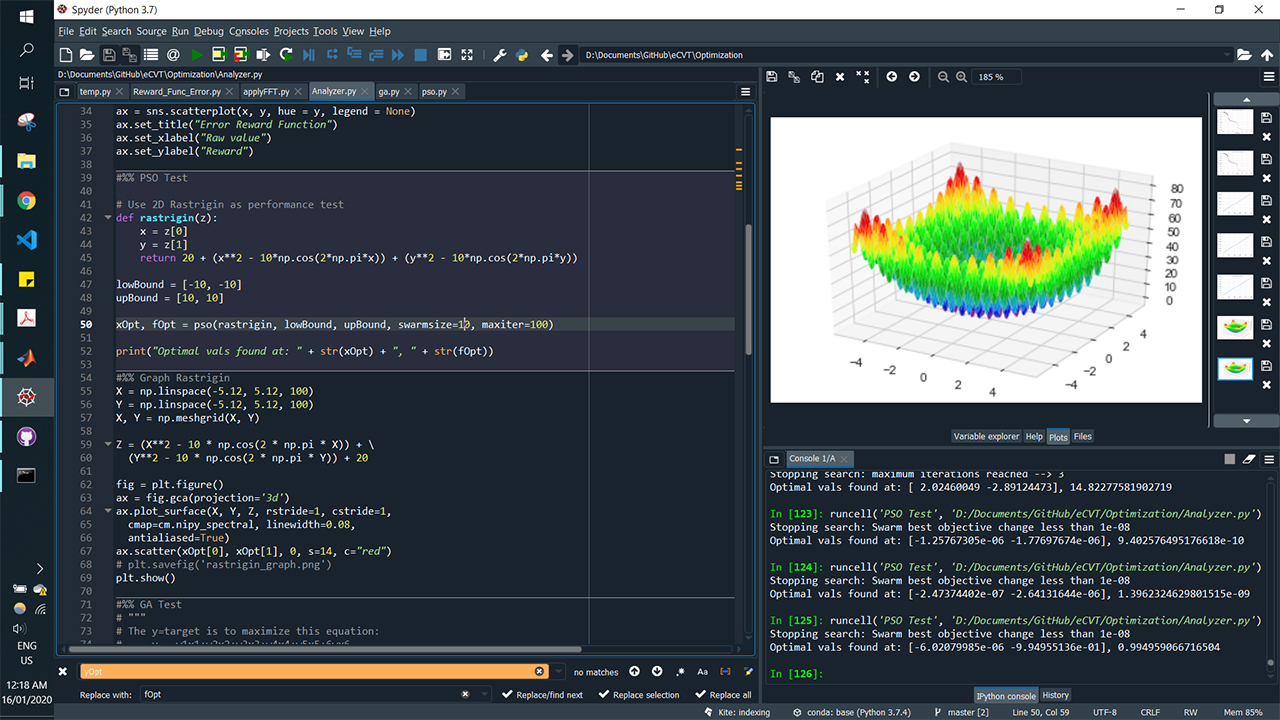

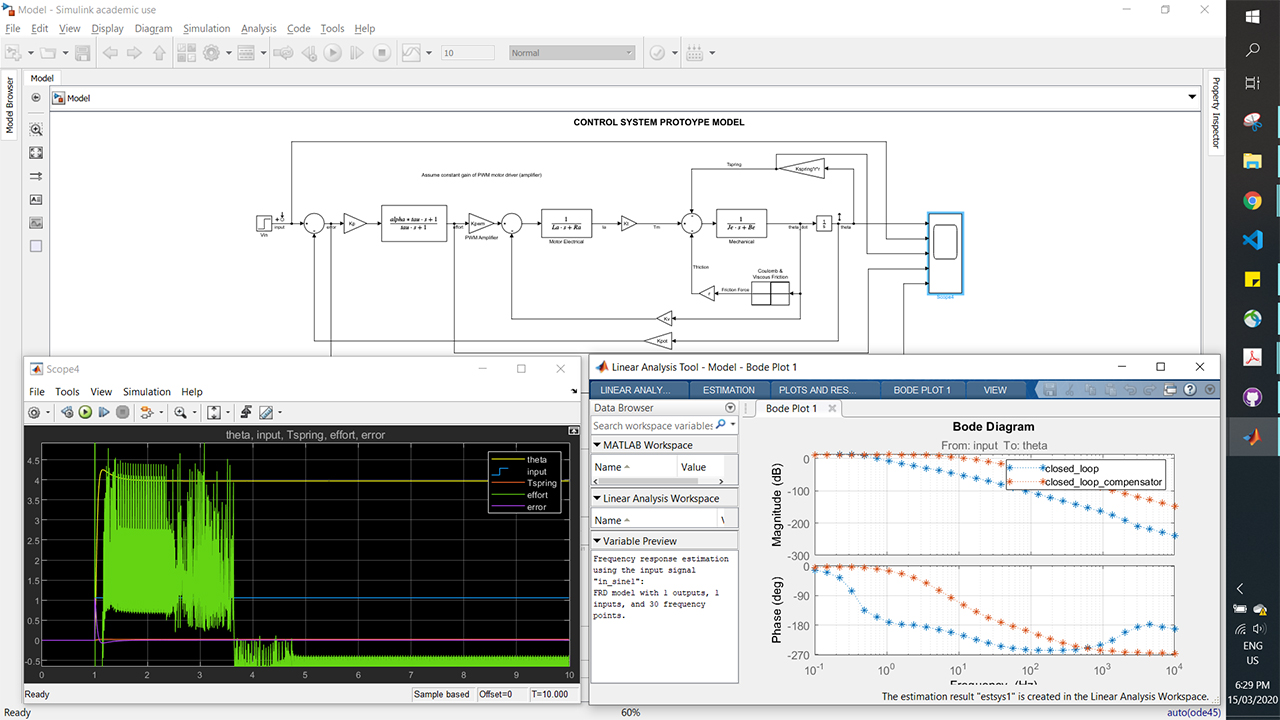

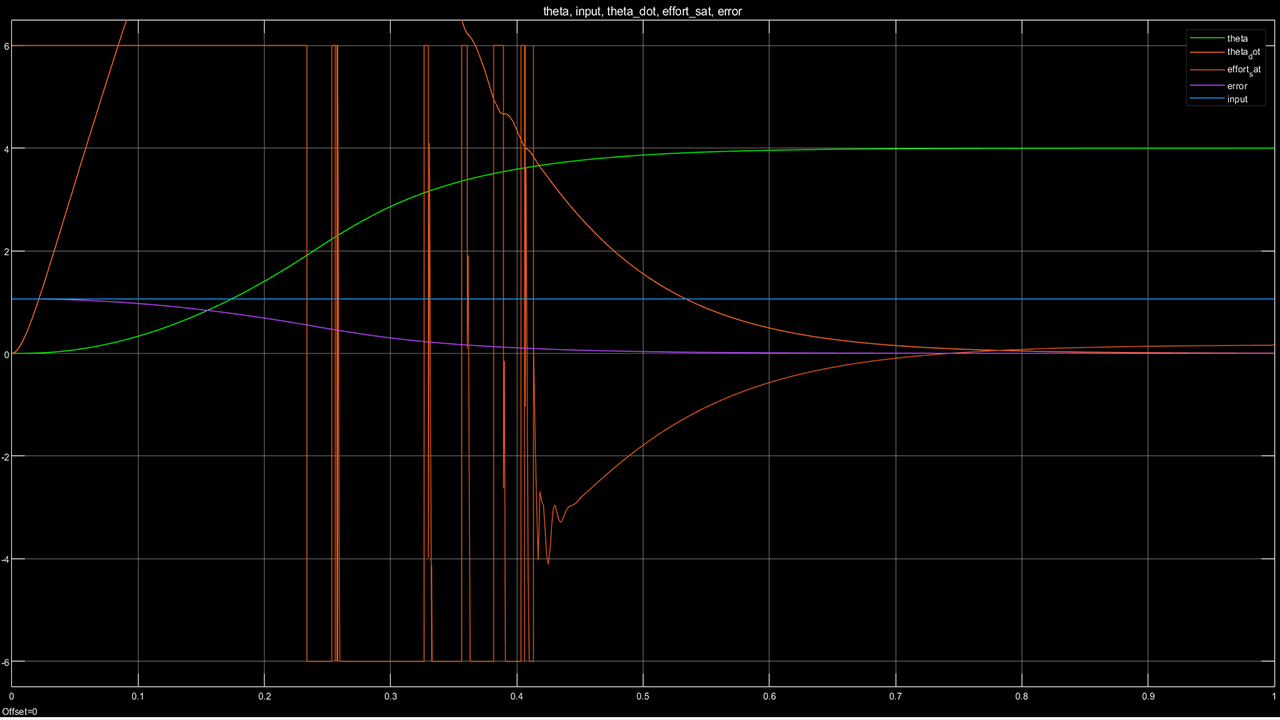

For my engineering capstone course, I joined the UBC Baja student design team in their efforts

to upgrade their continuously variable transition with an electronic one, allowing for better

race performance with fewer components, better control, and reduced tuning time.

Although my interests are in aircraft and aviation, this project provided valuable exposure

to automotive engineering. My role was to develop the controls and electrical systems; I

created a functional controls prototype to gain familiarity with modelling a real-life system

before creating a mathematical model of the eCVT and performing simulations in Simulink,

using loop shaping to derive a controller.

While the full controller was unable to be simulated, tested, and integrated onto the Baja

vehicle due to COVID19, our capstone team's prototype was the most complete and mature among

all teams in the course. Next steps would have been to generate a frequency

sweep of the eCVT, design a controller around the model (maybe with state feedback), simulate

with a realistic sheave load, flash the microcontroller (with auto code generation), finalize

the protoboard circuit (with an enclosure and maybe with a PCB), and verify the system with a

battery of tests.

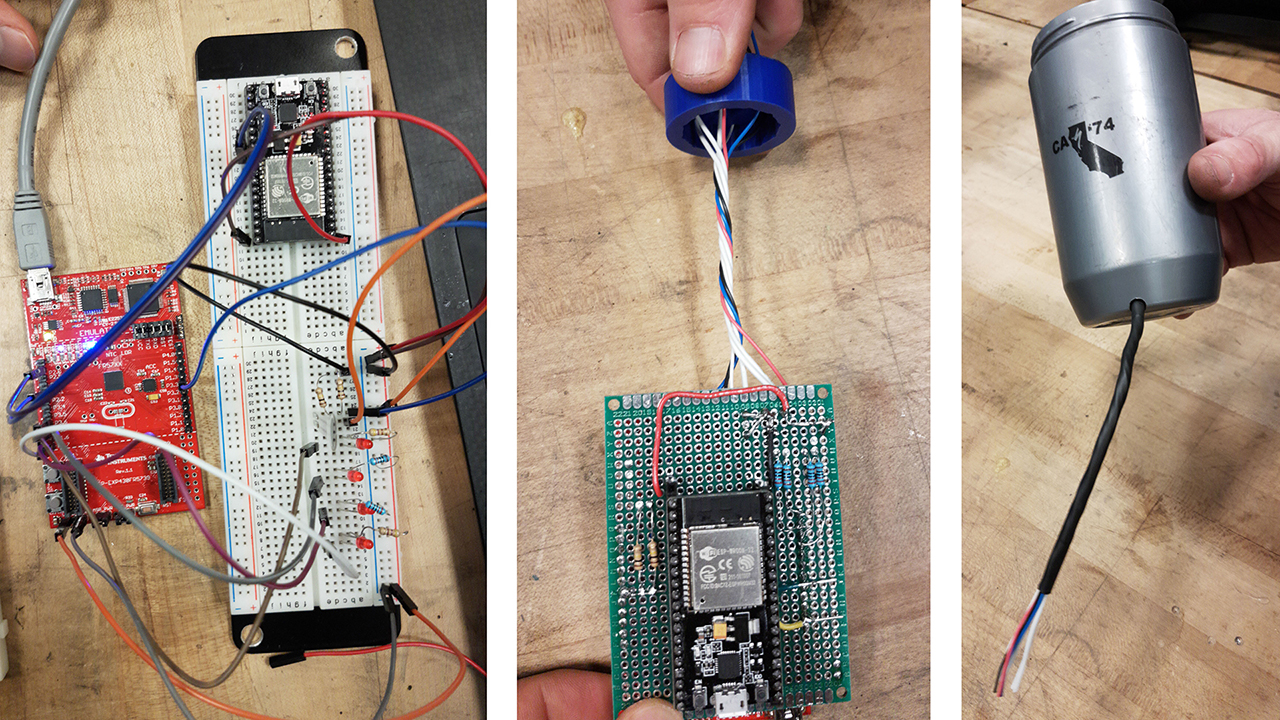

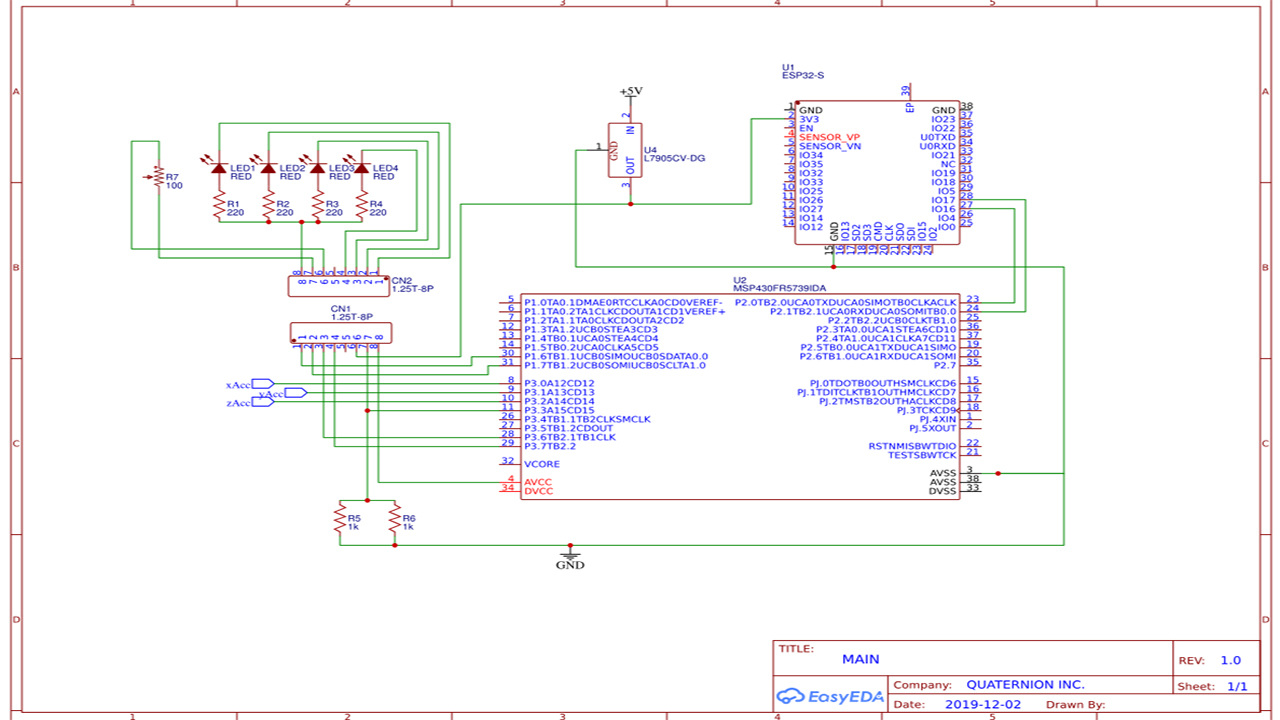

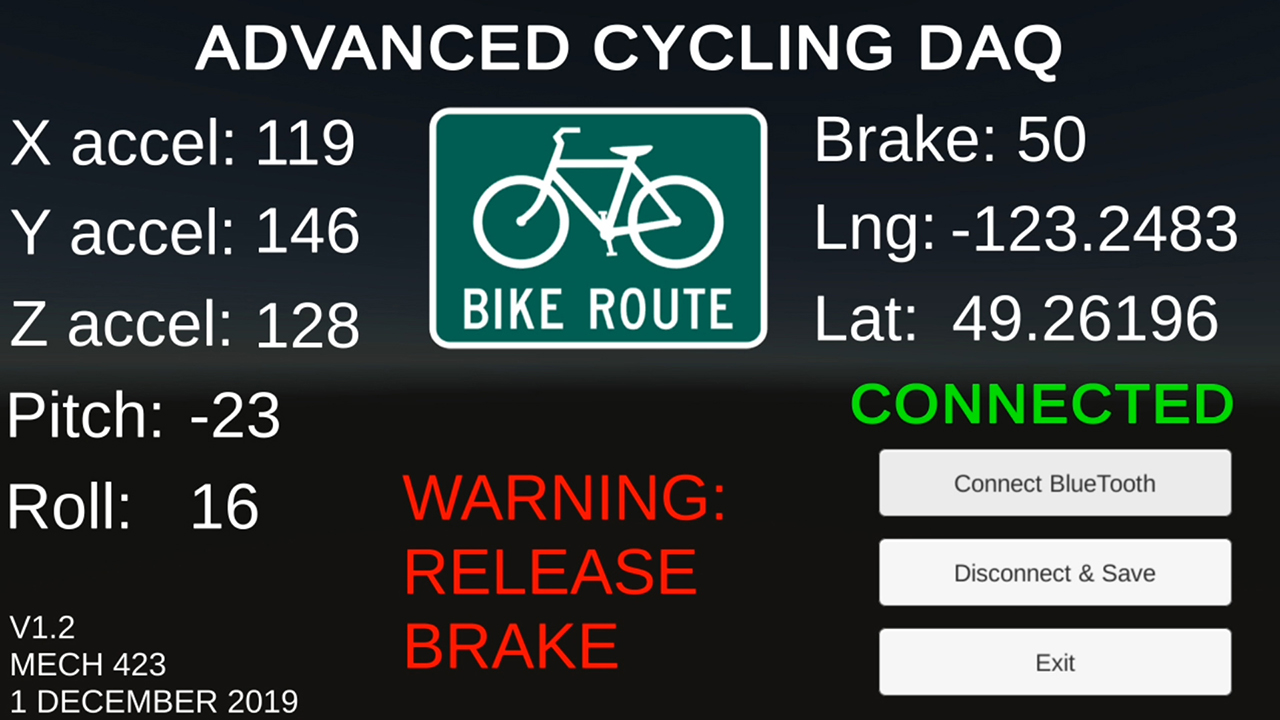

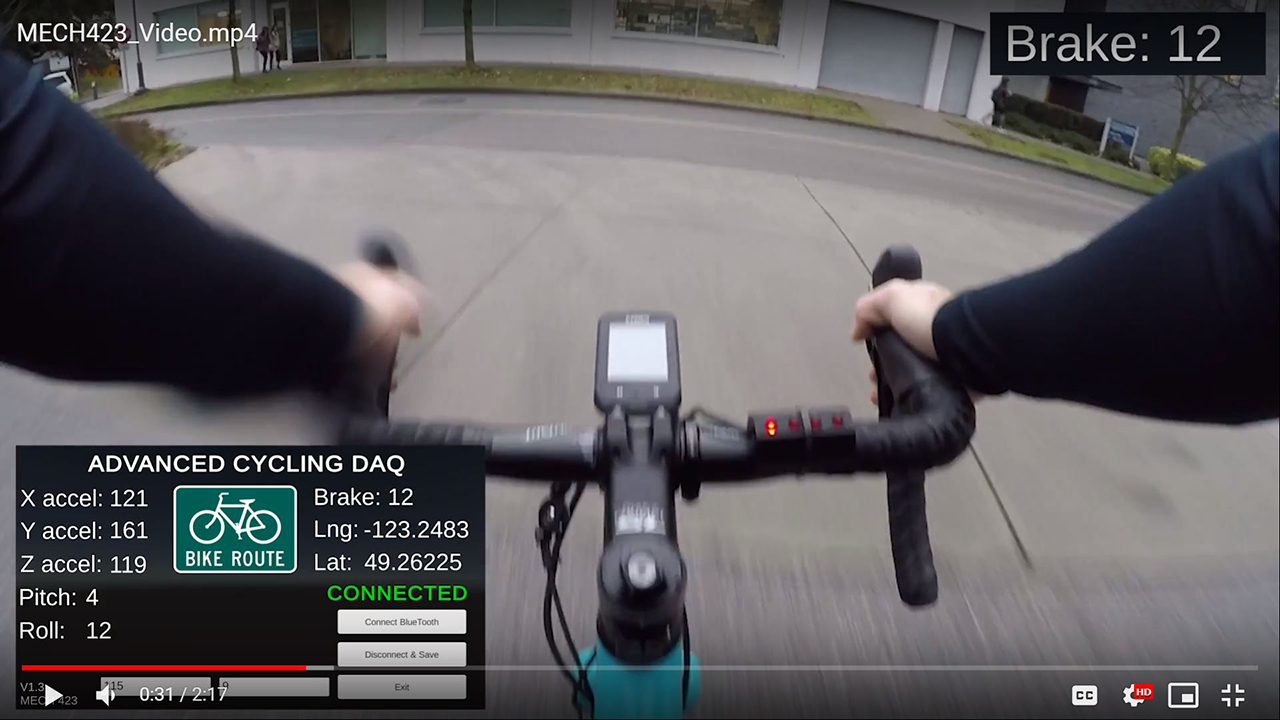

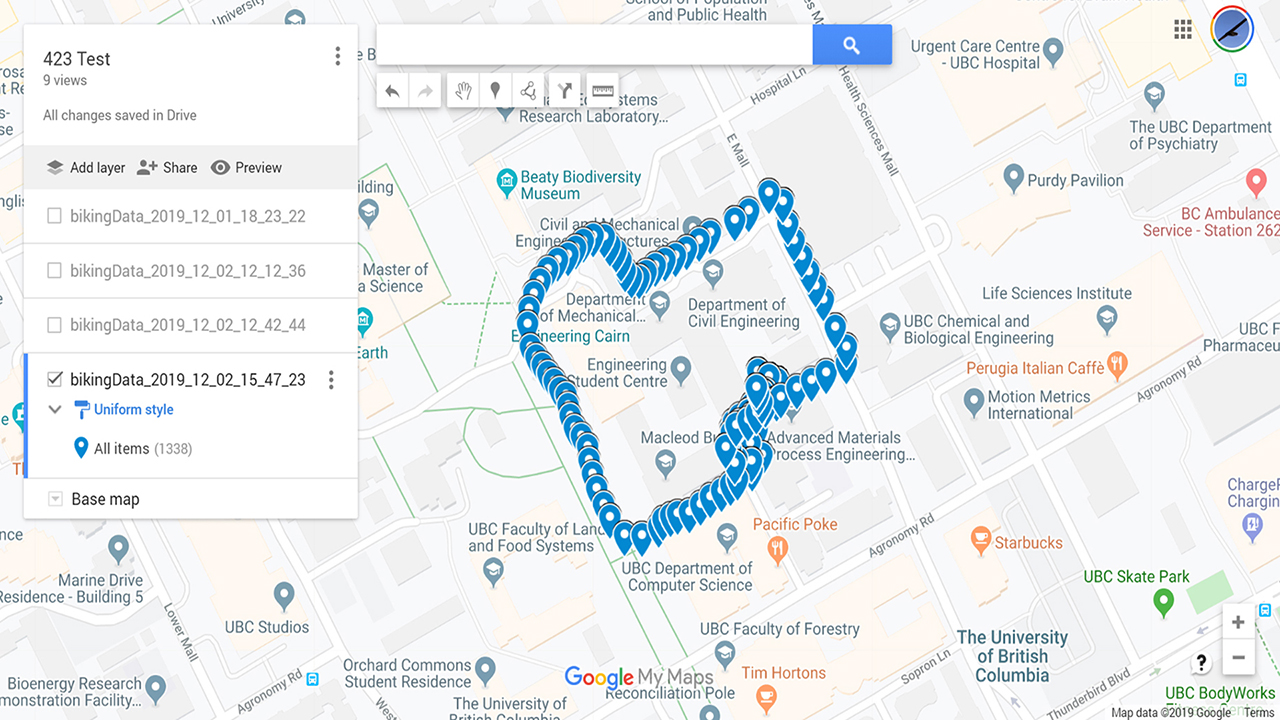

For the MECH423 Mechatronics Product Design course final project, I created a performance cycling DAQ unit.

I programmed an MSP430 to collect and transmit accelerometer and brake pressure data to an ESP32, before

broadcasting it over BlueTooth to a custom Android application I developed. Each data packet is populated

with time, longitude, and latitude from the phone GPS before being saved to a CSV file for analysis.

LEDs on the handlebar indicated brake activation, and if brakes are applied during a turn, an audible warning

is emitted from the app. Ingress protection is ensured by a modified water bottle housing the custom

perfboard circuit I made, mil-spec wiring, and automotive-grade connectors. The entire system was extensively

tested and validated in the rain on sidewalks and streets.

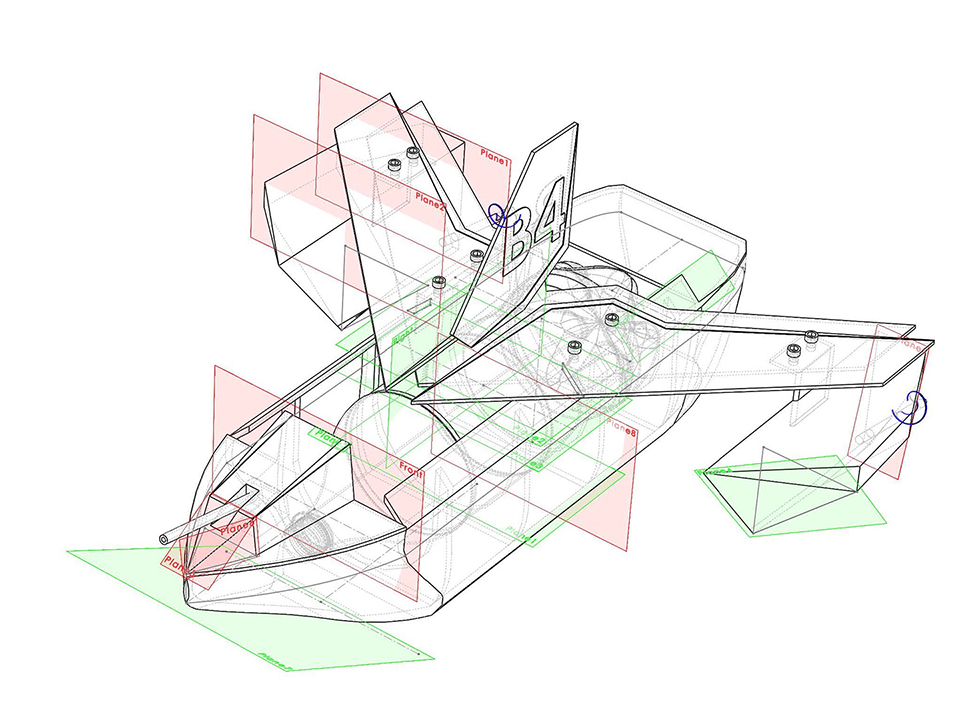

A scale model RC fireboat was built as part of the concluding MECH2 design project.

My team proceeded with a trimaran design after consultations with a renown naval

engineering professor. The design process was subsequently featured in an engineering design

textbook at the request of the UBC Mech2 Program Director.

The vessel was modelled and rendered with SolidWorks and optimized with SolidWorks CFD.

I designed the water cannon cupola, inspired by stealth technologies, while a servo motor

system provided water cannon trajectory control through pressure and elevation changes. An

RC receiver provided control of propulsion, steering, and water deployment. The high

maneuverability was achieved through trimaran hull and dual BLDC motors using alternating thrust.

© Raymond Yu